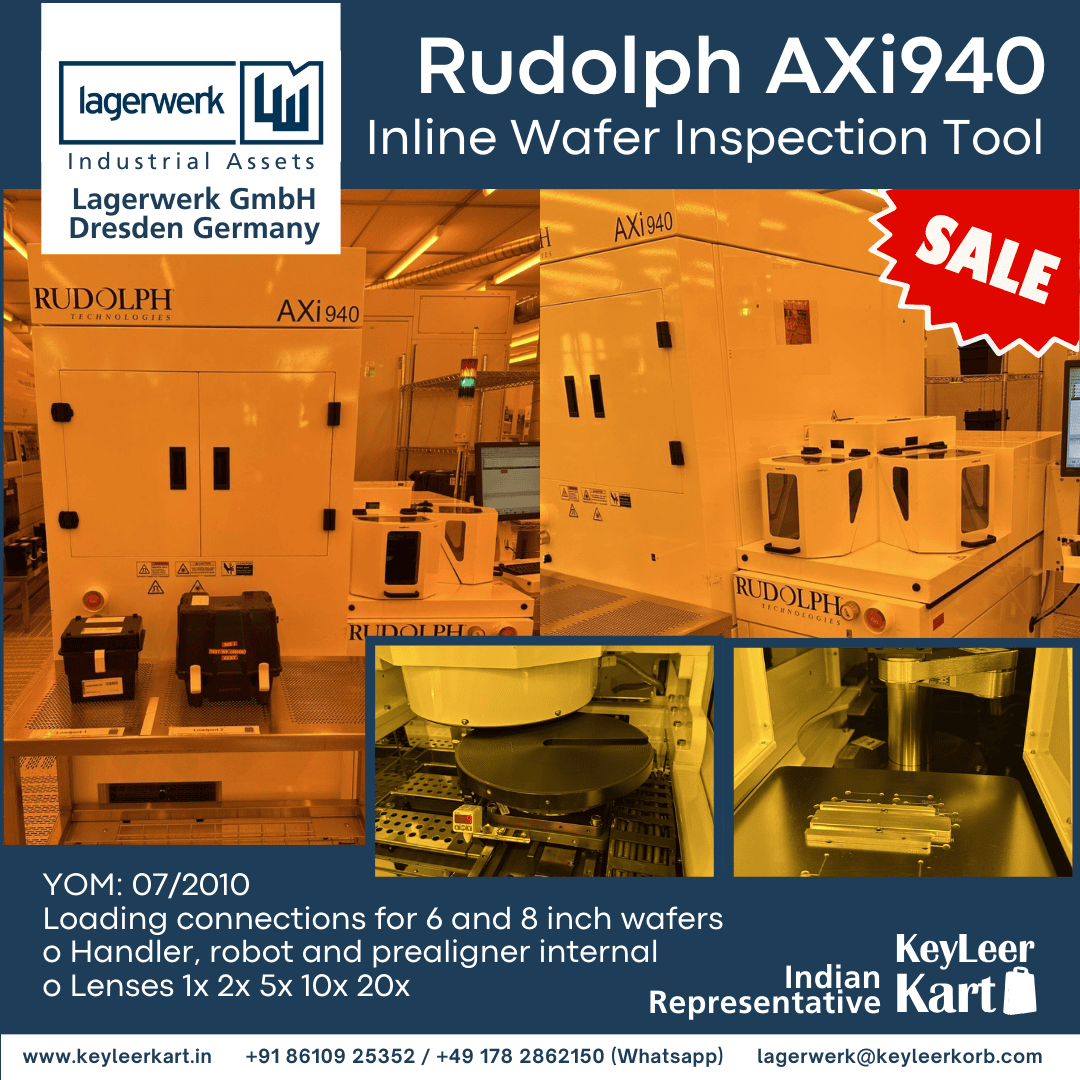

In today's competitive semiconductor and electronics manufacturing industries, defect detection and quality control are more important than ever. The Rudolph AXi 940B stands out as one of the most advanced macro defect inspection systems available today, offering unmatched precision, speed, and usability.

If you're searching for a reliable wafer inspection machine, a substrate defect detection tool, or an automated macro inspection system for your production line, the AXi 940B by Rudolph Technologies delivers performance, consistency, and exceptional return on investment.

🔍 What Is the Rudolph AXi 940B Macro Defect Inspection System?

The AXi 940B is a non-contact, optical inspection system designed to detect and classify macro-level defects such as cracks, scratches, particles, and edge damage on semiconductor wafers and substrates. It plays a crucial role in maintaining product quality, minimizing production losses, and meeting strict industry standards.

✅ Top Features and Benefits of the AXi 940B

📸 High-Speed, High-Resolution Imaging

Capture defects in high clarity with ultra-fast image processing. The AXi 940B delivers sharp, detailed visual data, reducing the risk of undetected surface flaws.

Keywords: high-speed wafer inspection, defect imaging system, macro inspection resolution

🛑 Non-Destructive and Non-Contact Inspection

Designed for sensitive semiconductor materials, the AXi 940B performs precise inspections without touching the product surface—ideal for advanced electronics manufacturing.

Keywords: non-contact wafer inspection, non-destructive defect detection

🧠 Advanced AI-Powered Defect Classification

Using proprietary software algorithms and artificial intelligence, the system can automatically classify and categorize defects, improving efficiency and reducing operator workload.

Keywords: AI defect classification, intelligent inspection system

🔄 Automated Integration and High Throughput

Seamlessly integrate into your automated production line for continuous inspection with minimal human intervention. This allows for consistent, round-the-clock quality monitoring.

Keywords: inline wafer inspection system, automated inspection for semiconductors

📦 Versatile for Multiple Wafer Sizes and Materials

The AXi 940B supports various wafer sizes and material types, including silicon, glass, and compound semiconductors, making it a flexible choice for multi-product facilities.

Keywords: substrate inspection, flexible wafer inspection machine

💡 Why Invest in the Rudolph AXi 940B?

✔️ Maximize Yield, Minimize Scrap

Early detection of surface and structural defects reduces waste, improves yields, and ensures that only high-quality products move to the next stage.

✔️ Lower Cost of Quality Control

Replace manual visual inspections with a faster, more accurate, and scalable solution. The AXi 940B ensures consistency while cutting down on labor costs.

✔️ Boost Traceability and Compliance

With real-time defect maps and data logging, it helps in quality audits, reporting, and compliance with global standards for electronics and semiconductor manufacturing.

Keywords: semiconductor quality control, wafer yield improvement, defect tracking system

🏭 Industry Applications of the AXi 940B Macro Defect Inspection System

📟 Semiconductor Industry

Wafer surface inspection (pre- and post-process)

Edge chipping and particle detection

Die-level defect mapping

📱 Electronics Manufacturing

Substrate and PCB macro inspection

Crack and scratch detection for consumer electronics

Display panel quality assurance

💉 Medical Device Manufacturing

Optical inspection of MEMS and micro-components

Ensures no visual defects in life-critical devices

🔋 Automotive Electronics

High-reliability inspection for power devices and ADAS components

Prevents field failures by ensuring top-quality control

🛰️ Aerospace and Defense

Inspects semiconductors and substrates used in high-stress applications

Detects minor surface defects before deployment

🏆 Conclusion: Elevate Your Production Line with Rudolph AXi 940B

For manufacturers looking to invest in automated wafer defect inspection, the Rudolph AXi 940B offers a future-ready solution that ensures maximum yield, precision, and reliability. Whether you're operating in semiconductors, electronics, automotive, or aerospace, this machine is built to meet the rigorous standards of modern manufacturing.

SEO Keywords Recap: macro defect inspection system, wafer inspection equipment, semiconductor inspection tools, high-resolution defect detection, optical inspection for wafers, substrate quality control, automated visual inspection for electronics

📞 Ready to Improve Your Inspection Capabilities?

Contact us today to learn more about the Rudolph AXi 940B or to schedule a demo tailored to your industry. Discover how this world-class macro inspection system can add measurable value to your quality assurance and production workflow.