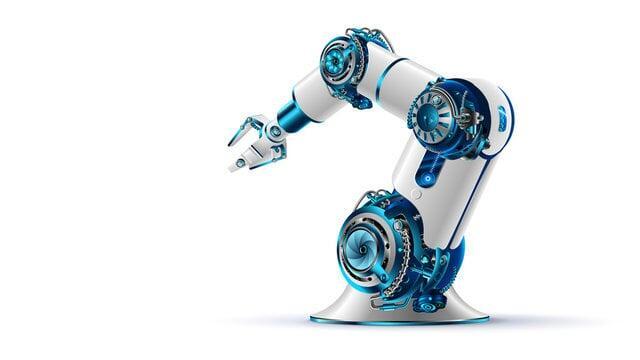

In today’s fast-paced world, industrial robots are revolutionizing the way manufacturing and heavy machinery operate. With the increasing demand for precision, efficiency, and productivity, industries are rapidly integrating robotics to stay ahead of the competition. At Keyleerkart, we are committed to bringing you the latest advancements in industrial automation and machinery.

Why Industrial Robots Are the Future of Manufacturing

Industrial robots have become the backbone of modern manufacturing. According to the International Federation of Robotics (IFR), global industrial robot installations have surged, highlighting the increasing reliance on automation. But why are businesses shifting towards robotic machinery? Here are some compelling reasons:

Increased Productivity: Robots can operate 24/7 without fatigue, significantly improving output.

Precision and Accuracy: With AI-driven control systems, industrial robots offer unmatched accuracy in manufacturing processes.

Cost Efficiency: Although the initial investment may be high, automation reduces labor costs and minimizes waste over time.

Enhanced Safety: Robotics eliminate the need for humans to work in hazardous environments, reducing workplace injuries.

The Role of Robotics in Machinery

From CNC machines to automated material handling systems, robotics are transforming various aspects of industrial machinery. At Keyleerkart, we specialize in providing state-of-the-art machinery that integrates seamlessly with robotic automation. Here’s how robotics are enhancing different types of machinery:

CNC Machines: Robotic arms assist in loading and unloading materials, improving efficiency.

Conveyor Systems: Automated conveyors reduce manual intervention, streamlining logistics.

Welding & Assembly Lines: Robots ensure precision in welding and assembling complex components.

Packaging & Palletizing: AI-powered robotic solutions enhance packaging speed and accuracy.

How Businesses Can Benefit from Robotic Automation

If you are in the manufacturing or industrial sector, integrating robotics can give your business a competitive edge. Here are some key benefits:

Scalability: Automated systems can be easily scaled up to meet growing production demands.

Reduced Downtime: Predictive maintenance through AI minimizes machine failures.

Energy Efficiency: Modern robots consume less power, making them environmentally friendly.

Customization: Robotic systems can be tailored to meet specific industry needs.

Keyleerkart: Your Trusted Partner in Industrial Machinery

At Keyleerkart, we offer a wide range of cutting-edge machinery designed to integrate with the latest robotic technology. Whether you are looking to upgrade your manufacturing setup or implement automation for the first time, our solutions cater to your needs.

Explore our collection of CNC machines, automated conveyor systems, robotic welding stations, and more at www.keyleerkart.in.

Stay Ahead in the Age of Automation

The future of industrial manufacturing is here, and robotics are at the heart of this transformation. Don’t get left behind—embrace automation today! Connect with Keyleerkart to discover how industrial robotics can take your business to the next level.

For expert guidance on industrial automation and machinery, visit www.keyleerkart.in today!