A Comprehensive Guide

When it comes to purchasing machinery, businesses often face a key decision: Should they opt for brand-new equipment or invest in second-hand machinery? As a reseller of second-hand machines, we understand the importance of making informed choices that balance cost, functionality, and long-term value. This comprehensive guide will walk you through the key considerations when deciding between new and used machinery, helping you make the right choice for your operational needs.

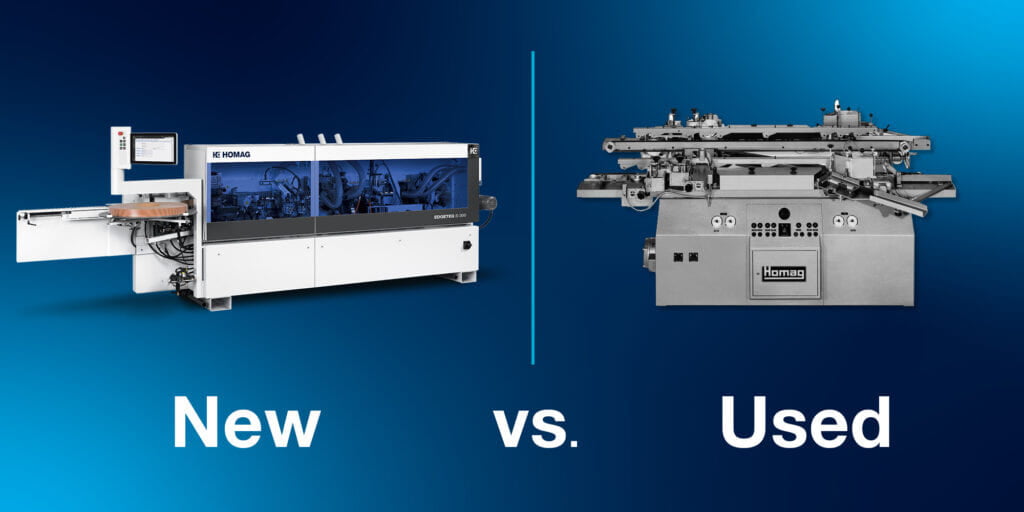

Understanding the Difference: New vs. Used Machinery

New Machinery

New machinery refers to equipment that has never been used before, usually purchased directly from manufacturers or authorized dealers. Here's what you can expect:

- Latest Technology: New machines are equipped with cutting-edge technology and advanced features designed to optimize productivity and efficiency.

- Warranty: New equipment typically comes with a full manufacturer's warranty, offering coverage for repairs and defects, along with reliable service support.

- Condition: Pristine and in perfect working condition with no prior usage or wear.

Used Machinery

Used machinery, on the other hand, has been previously owned and operated. It is either sold as-is or may have been refurbished. Key characteristics include:

- Previous Usage: The equipment has been used before, which may impact its performance and condition.

- Condition: The state of used machinery can range from lightly used and well-maintained to heavily worn, depending on how it was handled by its previous owners.

- Warranty: Warranties for used machinery may be limited or even non-existent, though some sellers offer refurbishment guarantees or extended service options.

Key Factors to Consider

Cost

- New Machinery: Higher upfront costs due to the latest technology and perfect condition, but you may benefit from lower short-term maintenance expenses.

- Used Machinery: More affordable, which makes it a budget-friendly option, though long-term maintenance and repair costs might be higher.

Technology and Features

- New Machinery: Equipped with the latest features that boost operational efficiency and productivity.

- Used Machinery: May not have the latest innovations, but older technology is often still functional and sufficient for many businesses.

Warranty and Support

- New Machinery: Comprehensive warranties and strong manufacturer support come standard.

- Used Machinery: Warranty options vary. Ensure you know what support is available before making a purchase.

Condition and Maintenance

- New Machinery: No wear and tear, minimal maintenance required initially.

- Used Machinery: Thorough inspections are essential. Reviewing the machine’s maintenance history will provide insights into future servicing needs.

Depreciation

- New Machinery: Rapid depreciation, especially within the first few years.

- Used Machinery: Depreciates more slowly since the major drop in value has already occurred, allowing for a more stable resale value.

Availability

- New Machinery: Delivery lead times may be long, depending on the manufacturing and supply chain.

- Used Machinery: Often available immediately, which is beneficial for businesses with urgent needs.

Customization

- New Machinery: Can be tailored to your specific operational requirements.

- Used Machinery: Limited customization options, though some retrofitting may be possible depending on the machine.

Making the Right Decision

Choosing between new and used machinery depends on your specific needs and long-term goals. Here are a few tips to help you decide:

- Assess Your Operational Needs: Do you need the latest technology, or will older machinery suffice? Understanding your current and future requirements is key.

- Inspect Thoroughly: When considering used equipment, always conduct a thorough inspection or hire a professional to assess the machine's condition.

- Compare Costs: Weigh the initial purchase price against potential long-term maintenance expenses. Remember, used machinery might come with lower upfront costs but could lead to higher maintenance needs down the road.

- Consider Long-Term Value: Evaluate whether the machine will meet your future needs or if it might need upgrades to remain competitive.

Why Buy Used Machinery from Us?

At KeyLeer Automation Solutions, we specialize in providing high-quality second-hand machinery that offers great value without sacrificing reliability. Our inventory includes machines that have been thoroughly inspected, refurbished, and are ready for immediate purchase. We help businesses meet their operational needs while keeping costs under control. Our long-standing expertise ensures that you’re not only getting a cost-effective solution but one that performs just as you need it to.

Follow Our Blog for More Insights

Making the right decision between new and used machinery requires careful consideration of both your budget and your operational requirements. Stay informed by following our blog, where we regularly share insights on how to maximize value when investing in machinery. Whether you’re in the market for used machines or simply looking for tips on maintaining your current equipment, we’ve got you covered.

If you're looking for reliable second-hand machines, contact us today or browse our inventory online. Let us help you find the right machine for your business!