India’s Manufacturing Vision: The Road to $1 Trillion

India’s manufacturing sector contributes ~17% to GDP (as of 2023, per IBEF), but the government aims to elevate this to 25% by 2030. Key pillars of this vision include:

Boosting exports: Targeting $1 trillion in goods exports by 2030.

Empowering MSMEs: SMEs contribute 29% to India’s GDP and employ over 120 million people.

Adopting Industry 4.0: Integrating automation, IoT, and smart manufacturing.

Sustainability: Reducing waste through circular economy practices.

However, high capital costs for advanced machinery remain a barrier for smaller players. This is where used CNC machines bridge the gap.

The Role of Used CNC Machines in Achieving the

$1 Trillion Goal

1. Cost-Effective Automation for SMEs

New CNC machines can cost ₹50 lakh to ₹5 crore, putting them out of reach for many SMEs. Used CNC machines, on the other hand, are 30–60% cheaper, enabling smaller businesses to automate processes and compete globally.

Case in Point: A Coimbatore-based auto parts manufacturer reduced production costs by 40% after purchasing a used German CNC lathe, allowing them to bid for international contracts (Manufacturing Today).

2. Faster Adoption of Advanced Technology

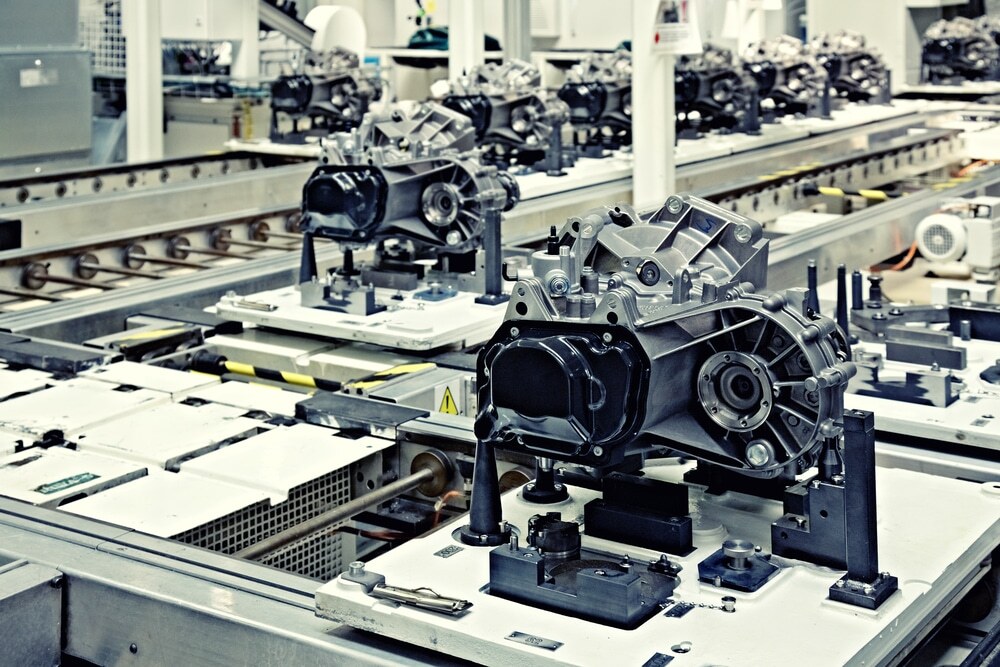

Used CNC machines from Germany, Japan, or the U.S. often feature cutting-edge technology (e.g., multi-axis capabilities, IoT integration) at a fraction of the cost.

Stat: India’s CNC machine market is growing at a CAGR of 7.9% (2023–2030), driven by demand for precision engineering in sectors like aerospace and automotive (Mordor Intelligence).

3. Sustainability and Circular Economy

Buying used machinery aligns with global sustainability trends. Refurbishing and reusing CNC machines reduces electronic waste and carbon footprints.

Stat: The global used machinery market is projected to grow at 6.2% CAGR by 2030, with Asia-Pacific leading demand (Grand View Research).

4. Scaling Production Capacity

To meet export targets, manufacturers need scalable solutions. Used CNC machines allow factories to:

Add production lines without massive upfront investment.

Quickly pivot to meet demand for high-precision components in sectors like EVs and defense.

Challenges and Solutions

Challenge 1: Perceived Reliability Issues

Some manufacturers hesitate to buy used CNC machines due to concerns about wear and tear.

Solution: Partner with certified sellers who provide refurbished machines with warranties. For example, Keyleerkart offers 100% tested, ISO-certified used CNC machines with service support.

Challenge 2: Skill Gaps

Advanced CNC machines require trained operators.

Solution: Government programs like the Skill India Mission and private-sector training partnerships are closing this gap.

Challenge 3: Maintenance Costs

Older machines may need more frequent upkeep.

Solution: Predictive maintenance tools and IoT sensors can monitor machine health in real-time, reducing downtime (Forbes).

Case Study: How Used CNC Machines Power India’s EV Revolution

The electric vehicle (EV) sector is a cornerstone of India’s manufacturing vision. Startups like Ola Electric and Ather Energy rely on precision components for batteries and motors.

Example: A Pune-based EV parts supplier sourced used 5-axis CNC machines from Germany to produce complex battery housings at 50% lower capital cost, enabling them to scale production for major OEMs (Economic Times).

Government Policies Supporting Used Machinery Adoption

Make in India 2.0: Focuses on boosting SME competitiveness through technology adoption.

PLI Schemes: Offers incentives for manufacturers in sectors like electronics, automotive, and drones.

Zero Defect Zero Effect (ZED) Certification: Encourages MSMEs to adopt efficient, high-quality machinery.

Statistical Insights

The Indian used machinery market is valued at $5.2 billion in 2024 and growing at 8% CAGR (IMARC Group).

Over 65% of Indian SMEs consider cost savings the primary reason for buying used machinery (CNBCTV18).

Why German Used CNC Machines?

Germany is a global leader in precision engineering, and its CNC machines are renowned for durability and innovation. For instance:

DMG Mori and Trumpf machines retain 70–80% of their precision even after decades of use.

German-engineered CNC systems often comply with global certifications, easing compliance for export-focused Indian manufacturers.

Conclusion: Used CNC Machines – A Catalyst for Growth

India’s $1 trillion manufacturing vision hinges on making advanced technology accessible to SMEs and reducing reliance on imports. Used CNC machines offer a pragmatic solution by:

Lowering entry barriers for automation.

Supporting sustainable manufacturing practices.

Enabling rapid scaling of production.

At Keyleerkart, we empower Indian manufacturers with high-quality, refurbished CNC machines from Germany. Explore our inventory to find machinery that aligns with your growth goals and India’s industrial ambitions.

Call to Action: Ready to contribute to India’s manufacturing revolution? Browse our curated selection of used CNC machines

at www.Keyleerkart.in or contact our experts for a personalized consultation.

Credible Sources Linked:

By leveraging data-driven insights and credible sources, this blog positions your business as a thought leader while aligning with India’s national goals. It also drives organic traffic through SEO keywords like “used CNC machines India,” “German CNC machines,” and “$1 trillion manufacturing vision.”