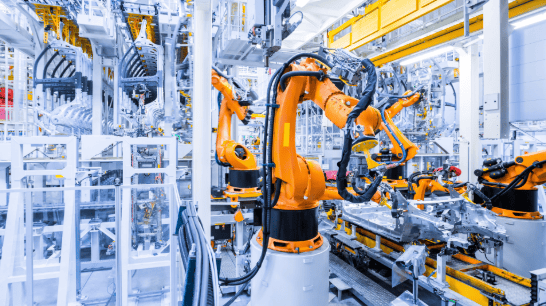

The import of second-hand industrial machinery into India is an increasingly prevalent trend, offering a compelling avenue for businesses to achieve significant cost savings and gain access to advanced technologies. While the prospect of acquiring machinery at a reduced price is attractive, navigating the intricacies of import regulations, ensuring the quality of used equipment, and understanding long-term ownership considerations are crucial for a successful venture. This report provides a comprehensive guide for Indian buyers and machinery dealers involved in the trade of second-hand industrial machinery, with a specific focus on CNC machines, lathes, robotic arms, and heat machines. It aims to illuminate the economic advantages, regulatory landscape, market demand, quality standards, global sourcing options, sustainability aspects, the role of online marketplaces, and the factors influencing the lifespan and maintenance of imported used machinery. Furthermore, this report highlights the role of platforms like Keyleerkart in facilitating this trade, serving as a valuable resource for connecting buyers and sellers in the Indian market.

2. The Economic Case for Used Machinery:

2.1. Cost Comparison: New vs. Used CNC Machines:

A fundamental driver for considering the import of second-hand industrial machinery is the substantial price difference compared to purchasing new equipment, particularly in the realm of CNC machines. New entry-level CNC milling machines, for instance, are typically priced between $10,000 and $30,000 , with high-end models potentially ranging from $100,000 to $500,000. Similarly, entry-level CNC routers have a price range of $5,000 to $20,000, while advanced industrial routers can cost $200,000 or more. In contrast, the market for used CNC machines presents significantly lower entry points, with basic options starting from around $2,000 to $5,000. Mid-range used CNC machines with more advanced capabilities can be found in the range of $10,000 to $100,000 or even higher, depending on their specifications and condition. This price disparity underscores the potential for considerable financial benefits when opting for used machinery. In many instances, used machines can be acquired for a fraction of the cost of their brand-new counterparts , with savings potentially ranging from several thousand to hundreds of thousands of dollars depending on the type and complexity of the machine. Data from Keyleerkart indicates a growing acceptance and demand for this cost-effective solution in India, evidenced by a 20% year-on-year increase in the sale of used CNC machines on their platform. This trend suggests that small and medium-sized enterprises (SMEs) in India are increasingly recognizing the economic advantages of used CNC machinery, especially in light of the growing need for automation in their manufacturing processes. The lower initial investment associated with used CNC machines can significantly reduce the financial barrier for businesses seeking to upgrade or expand their manufacturing capabilities, allowing for a quicker adoption of advanced technologies that might otherwise be financially prohibitive. Furthermore, within a given budget, businesses might find that purchasing a used machine allows them to acquire a higher-specification model compared to a new entry-level option, thereby gaining access to enhanced features and potentially greater productivity. For example, a used Mazak HCN 5000-II, which originally cost around $400,000 when new, was available for $150,000 and featured a recently replaced spindle, illustrating the potential to access high-performance machinery at a significantly reduced cost.

2.2. Cost Comparison: New vs. Used Lathes, Robotic Arms, and Heat Machines:

While direct comparative pricing data for new versus used lathes, robotic arms, and heat machines in a consolidated format is limited, the general principle of lower costs for used industrial equipment observed with CNC machines extends to these categories as well. Entry-level CNC lathe machines typically have a new price range of $10,000 to $30,000, with high-end models reaching $100,000 to $500,000. New industrial robot systems can range from $20,000 to over $100,000 , but refurbished models are often available at approximately half the price. Basic 2-axis CNC machines, suitable for fundamental drilling and turning operations, range from $5,000 to $50,000 when new , while 3-axis CNC milling machines typically cost between $10,000 and $150,000. The consistent trend across these different types of industrial machinery indicates that significant financial savings can be realized by opting for used equipment. This cost-effectiveness enables Indian manufacturers to potentially diversify their machinery portfolio by acquiring a combination of used equipment across various categories at a lower overall expenditure compared to investing solely in new machines. Such a strategy provides greater flexibility for staged upgrades and expansions, allowing businesses to optimize their capital allocation based on their immediate operational needs and budgetary constraints.

2.3. Return on Investment (ROI) Considerations:

The lower initial capital outlay required for used machinery directly contributes to a more favorable Return on Investment (ROI) for Indian manufacturers. Used machinery from reputable brands can enhance ROI due to its competitive pricing. A compelling example of this is the case study of an automotive component manufacturer in Pune who invested in a used CNC machine sourced from Germany through Keyleerkart and achieved a full ROI within just 18 months. The basic formula for calculating ROI is: (Gains - Costs) / Costs. Given the reduced cost of acquisition for used machinery, the potential for a quicker return on the invested capital becomes evident. While new machines undoubtedly offer the latest technological advancements and are typically accompanied by comprehensive warranties, used machines can provide a faster route to profitability due to their lower upfront costs. Used and refurbished robots, for example, offer the prospect of a quicker ROI as their initial purchase price is considerably lower. However, it is crucial to acknowledge that the calculation of ROI for used machinery must also factor in potential maintenance expenses and the possibility of repairs. These costs, along with potential downtime, should be carefully considered as part of the overall investment evaluation. Despite these considerations, the relatively stable value of used machinery after its initial depreciation period can lead to a better resale value in the short term compared to new machinery, which often experiences a rapid decline in value in its early years. This stability in value can allow businesses to potentially recoup a larger portion of their initial investment should they decide to sell the equipment at a later stage.

2.4. Factors Influencing the Cost of Used Machinery:

The price of used industrial machinery is influenced by a multitude of factors, including the specific type of machine, the reputation and quality of the brand, its age, its current condition, the features it offers, and the overall reputation of the original manufacturer. For instance, used machines that have been primarily used for processing lighter materials like aluminum or plastic might be in better overall condition compared to those that have been subjected to heavy-duty applications. In fact, an ideal scenario for a used machine is one where it has been used solely for cutting aluminum or plastic and has never sustained any significant damage or crashes. Before committing to a purchase, a thorough inspection and testing of the used machinery is paramount. The specific application for which the machine was previously used and the intensity of that usage have a significant impact on its present value and its potential remaining lifespan. A machine that operated in a high-volume production environment might exhibit more wear and tear compared to an identical machine that saw only occasional use in a maintenance or repair shop, even if they were manufactured in the same year. Therefore, machines originating from production-intensive settings should generally be approached with greater scrutiny. Ultimately, making an informed investment often involves choosing a well-maintained machine from a reputable brand, even if it is slightly older, over a newer but potentially less reliable or lower-quality option. Well-established brands often adhere to higher manufacturing standards, resulting in greater durability and potentially longer service lives. Moreover, these brands typically offer better after-sales support and a more readily available supply of spare parts, making them a more sustainable investment in the long run. The fundamental quality of the manufacturing process itself also plays a crucial role in determining the overall cost and value of a machine.

3. Navigating the Import Regulations:

3.1. Overview of Import Policies for Second-Hand Goods:

Understanding the regulatory framework governing the import of second-hand industrial machinery into India is essential for both buyers and dealers. According to the Directorate General of Foreign Trade (DGFT) guidelines, the import policy outlined in Schedule 1 of the Indian Trade Classification (Harmonised System) is generally applicable to new goods. The specific policy for second-hand goods is detailed in Paragraph 2.31 of the Foreign Trade Policy (FTP). As a general rule, the import of second-hand capital goods, which includes refurbished or reconditioned spares, is permitted freely. However, this allowance has specific exceptions, notably for items such as personal computers, laptops, photocopier machines, air conditioners, and diesel generating sets, which are classified as restricted and require an import license from the DGFT. Therefore, while a significant portion of industrial machinery can be imported without specific licensing, it is imperative for importers to meticulously verify the specific classification of their intended equipment under the prevailing Foreign Trade Policy to ensure full compliance with Indian regulations. Misclassifying machinery can lead to a host of complications, including potential delays in customs clearance, financial penalties, or even the outright rejection of the import shipment. To avoid such issues, importers should consistently consult the most up-to-date versions of the FTP and the ITC (HS) codes.

3.2. Specific Regulations for Lathes and Heavy Industrial Machinery:

Within the broader category of second-hand capital goods, certain provisions within the FTP offer additional clarity for the import of lathes and other heavy industrial machinery. Notably, second-hand capital goods, irrespective of their age, can be imported under the Export Promotion Capital Goods (EPCG) scheme. Furthermore, the FTP also allows for the duty-free import of second-hand capital goods, again without any age-related restrictions. While older DGFT guidelines from 1999 did suggest age-based limitations on the import of second-hand capital goods, with restrictions particularly on machinery older than 10 years unless it was classified as heavy equipment for infrastructure or core sector industries , the current policy under the FTP 2015-2020 (Paragraph 2.31) generally permits the free import of most second-hand capital goods. A fundamental prerequisite for engaging in any import activity, including the import of second-hand machinery, is obtaining an Import Export Code (IEC). This code is mandatory for all entities involved in the import or export of goods into or out of India. The absence of stringent age limitations on the import of most second-hand capital goods presents a considerable advantage for Indian businesses, as it broadens the spectrum of machinery they can potentially access from international markets. This flexibility allows companies to identify and acquire machinery that precisely aligns with their specific operational requirements and budgetary constraints, without being unduly restricted by the equipment's year of manufacture, provided that it meets the requisite quality and safety standards.

3.3. Import Procedures and Documentation:

The process of importing goods into India, including second-hand industrial machinery, involves a series of well-defined steps. These typically include first obtaining the mandatory Import Export Code (IEC), followed by ensuring adherence to all relevant trade laws and regulations. Depending on the specific type of machinery, procuring an import license from the DGFT might also be necessary. Subsequently, importers are required to file a Bill of Entry, along with other essential documentation, to fulfill customs clearing formalities and finally, to determine and pay the applicable import duties for the clearance of the goods. Key mandatory documents that are generally required for the import of goods into India include the Bill of Lading or Airway Bill, the Commercial Invoice cum Packing List, and the Bill of Entry. A particularly crucial document in the context of importing second-hand machinery is the Chartered Engineer's certificate. This certificate plays a vital role in the valuation of the used machinery and in assessing its remaining useful life. For refurbished or reconditioned spares of capital goods, the Chartered Engineer's certificate must specifically attest that such spares retain at least 80% of the residual life of the original spare. The customs clearance process involves a thorough examination of the submitted documentation and may also include physical inspections of the imported goods. In certain instances, a pre-shipment inspection report might also be required. The Chartered Engineer's certificate serves as a critical piece of evidence for customs authorities, providing assurance regarding the condition, safety, and the estimated remaining useful life of the imported machinery, which ultimately facilitates a smoother customs clearance process. Given the often intricate nature of the documentation and procedures involved in importing machinery, it is highly advisable for importers to engage the services of experienced customs clearing agents. These professionals possess the expertise to navigate the complexities effectively, helping to avoid potential delays and ensuring full compliance with all applicable regulations.

3.4. Recent Changes and Challenges:

The regulatory landscape for machinery imports into India is subject to ongoing developments. A significant recent change is the increasing emphasis on aligning Indian safety standards for machinery with global norms. This is exemplified by the introduction of the 'Machinery and Electrical Equipment Safety (Omnibus Technical Regulation) Order, 2024'. This new regulation, which is set to come into effect on August 28, 2025, mandates stringent safety standards for all machinery and electrical equipment that is either manufactured in or imported into India. A key aspect of this order is the requirement for manufacturers and importers to obtain certification from the Bureau of Indian Standards (BIS) for a wide range of machinery. This upcoming regulation is likely to have a significant impact on the import of used machinery, as it will necessitate that such equipment complies with the specified safety standards to ensure smooth customs clearance after the effective date. While these new standards are aimed at improving safety and quality, they could potentially pose challenges for Micro, Small, and Medium Enterprises (MSMEs) due to the financial and technical resources required to meet these compliance standards. In addition to these evolving safety regulations, importers of used machinery into India also face other persistent challenges. These include relatively high import duties, which can impact the overall cost-effectiveness of importing, as well as the complexities of navigating India's tariff structure and the government's protectionist policies aimed at promoting domestic manufacturing. While the government's objective is to bolster local industries, high import duties on certain components that might be needed for upgrades or repairs of used machinery can inadvertently increase the total cost of ownership for importers. Therefore, it is crucial for businesses considering importing used machinery to conduct a thorough assessment of the equipment's condition and the potential costs associated with any necessary upgrades or spare parts, taking into account the applicable import duties on these items.

4. Understanding the Indian Market Demand:

4.1. Demand for Used Robotic Arms:

The Indian market for robotic arms is experiencing consistent growth, primarily driven by the increasing adoption of automation across a diverse range of industries, including automotive, electronics, healthcare, and general manufacturing. This upward trend is reflected in market size projections, with the Indian robotic arm market anticipated to reach a substantial value of USD 13.90 billion by the year 2032, demonstrating a Compound Annual Growth Rate (CAGR) of 13.1%. India's growing prominence in the global robotics landscape is further highlighted by its position among the top 10 countries worldwide in terms of annual robot installations. A key factor fueling this demand is the increasing recognition among businesses of the potential of robotic arms to significantly improve productivity and reduce reliance on manual labor. This burgeoning demand is also evident in the import data for used robots into India. According to Volza's import statistics, India imported a significant number of used robots, with 1,978 shipments recorded between March 2023 and February 2024. This indicates a strong appetite for pre-owned robotic equipment within the Indian market. Given the substantial cost advantages associated with used robotic arms , the robust growth trajectory of the Indian robotic arm market presents a considerable opportunity for businesses involved in importing and supplying these pre-owned automation solutions. As more industries in India embrace automation to enhance efficiency and precision in their operations, the demand for cost-effective robotic solutions, such as used and refurbished robotic arms, is expected to continue its upward climb.

4.2. Demand for Used Heat Machines:

The heat treating market in India is also demonstrating significant expansion, primarily propelled by the growth and demands of the automotive and aerospace industries. Market valuations for India's heat treating sector are projected to reach USD 8.37 billion by 2027, exhibiting a CAGR of 7.5% , and are further expected to climb to USD 6.79 billion by 2030, with a CAGR of 5.4%. A major driver behind this growth is the increasing utilization of high-strength steel in the automotive sector, driven by the need for lightweight vehicles that offer improved fuel efficiency. Moreover, there is a growing emphasis within the heat treating market on adopting green technologies and energy-efficient furnace solutions. The sustained expansion of the heat treating market in India, fueled by these key industrial sectors, signifies a rising demand for both new and used heat treatment machinery. Consequently, businesses that are either entering or expanding their presence in these sectors might find it economically advantageous to consider importing used heat treatment machines, provided that the equipment meets the necessary quality and efficiency standards.

4.3. Key Growth Sectors and Regional Preferences:

Several key sectors within the Indian economy are demonstrating a strong propensity for adopting industrial robots, creating significant growth opportunities for importers and suppliers. These sectors include the automotive industry, electronics manufacturing, healthcare, pharmaceuticals, and general manufacturing. The automotive industry has historically been the leading adopter of industrial robots in India , and the electronics sector is also emerging as a major consumer. Common applications for industrial robots in these sectors include assembly processes, welding operations, material handling tasks, and packaging. Geographically, certain regions in India are emerging as key industrial hubs driving the demand for industrial robots. These include the Delhi-NCR region, Pune, and Chennai. Additionally, the rapidly expanding e-commerce and logistics sectors are generating an increasing demand for automated material handling solutions, which often involve the use of robotic arms. For dealers involved in importing used robotic arms, focusing on the automotive and electronics sectors, particularly within these key industrial hubs, could be a strategic approach. These sectors exhibit high rates of automation adoption and are geographically concentrated, which can facilitate more effective and targeted marketing efforts. Furthermore, the burgeoning e-commerce and logistics industries represent a promising area for growth in the demand for automated material handling solutions, including pre-owned robotic equipment.

5. Ensuring Quality and Performance:

5.1. Common Quality Standards:

When importing second-hand industrial machinery into India, adherence to established quality standards is paramount. Imported goods are mandated to comply with all domestic laws, rules, regulations, technical specifications, and environmental, safety, and health norms that are applicable to domestically produced goods. A significant upcoming development in this regard is the 'Machinery and Electrical Equipment Safety (Omnibus Technical Regulation) Order, 2024'. This regulation, slated to take effect on August 28, 2025, will impose stringent safety benchmarks for machinery and electrical equipment manufactured or imported into India. A key requirement under this order will be mandatory certification from the Bureau of Indian Standards (BIS) for a wide range of machinery. Additionally, it is important to note that all imported goods intended for retail sale must also comply with specific labeling requirements as stipulated by Indian authorities. Importers must therefore ensure that the used machinery they intend to bring into India not only meets current regulations but is also prepared to comply with the evolving safety and quality standards, particularly the forthcoming BIS regulations. Non-compliance with these standards can lead to significant complications during the customs clearance process and may result in penalties or even the rejection of the imported equipment.

5.2. Inspection Processes:

A critical aspect of ensuring the quality and performance of imported second-hand machinery in India is the inspection process, which often involves a Chartered Engineer. A Chartered Engineer plays a vital role in inspecting and certifying the condition of the machinery, its mechanical performance, its adherence to safety standards, and its estimated residual useful life. In fact, obtaining a Chartered Engineer's Certificate (CEC) is a mandatory requirement for exporting used machinery to India and is essential for securing customs clearance. Indian customs authorities rely on inspection reports that are either issued at the port of loading by an overseas Chartered Engineer or, upon arrival in India, by pre-shipment inspection agencies (PSIAs) that are notified by the DGFT, or by Chartered Engineers who are empanelled by the respective Custom Houses. Notably, inspection reports issued by Chartered Engineers who are based in the country where the second-hand machinery is sold are also accepted by all Custom Houses in India. Furthermore, importers have the freedom to select any Chartered Engineer who is empanelled by the Custom House at the port of import to conduct the necessary inspection. This inspection process, involving qualified Chartered Engineers, is of paramount importance as it serves to verify the quality and the fair market value of the imported used machinery, thereby providing a crucial level of assurance to both the buyers in India and the customs authorities. This process is instrumental in preventing the import of machinery that is substandard or unsafe and in ensuring that the valuation of the equipment for customs duty purposes is accurate and fair.

5.3. Ensuring Reliability and Performance:

Beyond the formal inspection processes, Indian buyers of second-hand industrial machinery should undertake their own due diligence to ensure the reliability and performance of the equipment. It is highly advisable to conduct a thorough inspection of the machinery before making a purchase, either personally or by engaging a trusted third-party expert. Reviewing the machine's maintenance records can provide valuable insights into its history of care and its potential remaining lifespan. Preference should ideally be given to machines that have been used in controlled environments and for lighter applications, as these are more likely to be in better condition. Buyers should also consider sourcing their machinery from trusted sellers or established platforms like Keyleerkart, which often provide detailed inspection reports and some level of quality assurance. When evaluating the overall cost-effectiveness, it is essential to factor in any potential expenses related to repairs, upgrades, and the procurement of spare parts that might be necessary. This proactive approach to assessing the condition, history, and potential future needs of the used machinery is crucial for mitigating the inherent risks associated with purchasing pre-owned equipment and for ensuring that it will deliver reliable performance over its intended lifespan. A comprehensive evaluation of the machine's current condition, its past usage patterns, and its history of maintenance will empower buyers to make well-informed decisions and to avoid potential operational or financial challenges in the future.

6. Global Sourcing: Availability and Pricing:

6.1. Availability of Used Machinery:

Indian buyers and dealers seeking second-hand industrial machinery have access to a vast global marketplace offering a wide array of options. Used CNC machines, lathes, robotic arms, and heat machines are readily available from numerous international markets. Online platforms such as Alibaba and a multitude of international marketplaces serve as key resources for sourcing this equipment. The global nature of this market provides Indian buyers with extensive accessibility and a diverse selection of machinery across various types, brands, and price ranges. This broad availability empowers buyers to locate machinery that closely aligns with their specific technical requirements and budgetary constraints.

6.2. Pricing from Different International Markets:

The pricing of used industrial machinery for Indian buyers can vary significantly depending on the international market from which it is sourced. For instance, CNC routers are generally more affordable when purchased from Asian markets, particularly China and Southeast Asia, including India itself, compared to those originating from Europe. In Asia, basic models of CNC routers can start at prices as low as $2,000, whereas European CNC routers, often featuring more advanced technology and precision engineering, tend to be more expensive, with prices ranging from $8,000 to $30,000. Several factors influence the overall cost of CNC machines, including the type of machine, its size and capacity, the brand and the manufacturer's reputation, the specific features and technology incorporated, and the extent of any customization. Listings on platforms like Alibaba reveal a range of prices for used CNC machines being offered from both China and Germany. Notably, used CNC routers from China can be found for prices starting as low as $2,000. Additionally, import data indicates that used CNC lathes have been imported into India from a variety of countries, including Thailand, Italy, Taiwan, South Korea, Japan, and the USA. Sourcing used machinery from Asian markets, especially China, can often present significant cost advantages for Indian buyers, particularly for standard equipment like CNC routers, likely due to lower manufacturing and labor costs in these regions. Conversely, markets in Europe and North America might offer access to higher-specification or more specialized used machinery, although these may come at a comparatively higher cost. Buyers who require advanced features or have specific brand preferences might need to explore these markets, carefully weighing the higher price against the enhanced capabilities of the machinery.

6.3. Considerations for Indian Buyers:

When engaging in the global sourcing of used industrial machinery, Indian buyers should adopt a strategic approach to ensure they secure the best value. It is advisable to compare prices from a multitude of suppliers and across different brands to gain a comprehensive understanding of the market. Buyers should also actively look for any ongoing promotions, discounts, or seasonal sales that might be available. Considering the option of purchasing refurbished or used machines, rather than solely focusing on new equipment, can unlock significant cost savings. Furthermore, engaging in negotiations with the supplier is often a viable way to potentially reduce the asking price. It is crucial for Indian buyers to conduct a thorough cost analysis that encompasses not only the initial purchase price of the machinery but also all associated expenses, such as transportation, installation, ongoing maintenance, and any anticipated repairs. Overlooking these supplementary costs can lead to an inaccurate assessment of the true financial implications of importing used machinery. Additionally, when considering shipping terms, buyers should pay close attention to details such as CIF (Cost, Insurance, and Freight), FOB (Free on Board) Port, and Ex Works, as these terms dictate the responsibilities and costs associated with the shipment.

7. Sustainability and Environmental Impact:

7.1. Environmental Benefits of Using Refurbished Machinery:

Opting for refurbished industrial machinery offers significant environmental advantages by reducing the demand for new manufacturing, which in turn conserves valuable natural resources and lowers overall industrial emissions. By choosing pre-owned equipment, businesses directly contribute to minimizing their carbon footprint, as the energy-intensive processes associated with producing new machines are avoided. Furthermore, extending the lifespan of existing machinery helps to minimize waste by diverting equipment from landfills, thereby reducing the environmental burden of disposal. In many cases, refurbished machines can also be retrofitted with modern, energy-saving features, further enhancing their sustainability credentials. The practice of importing and utilizing refurbished industrial machinery aligns strongly with the principles of a circular economy, which emphasizes the reuse and repurposing of resources to promote environmental sustainability and minimize waste. By embracing used equipment, businesses actively participate in a more resource-efficient and environmentally responsible manufacturing ecosystem.

7.2. Sustainability Aspects in India:

In India, there is a growing national focus on sustainability and the adoption of green practices across various sectors. The government is actively promoting domestic manufacturing and the development of renewable energy sources through various initiatives. Given this increasing emphasis on environmental responsibility, the import of used industrial machinery can be viewed as a sustainable practice that supports India's broader environmental goals. By giving functional equipment a second life, this practice reduces the demand for the energy-intensive production of new machinery, thereby contributing to a more sustainable industrial sector. This approach aligns with the global movement towards environmental stewardship and can enhance the environmental image and reputation of Indian businesses that choose to adopt it.

7.3. Potential Conflicts and Considerations:

While the use of refurbished machinery offers numerous environmental benefits, it is important to acknowledge potential concerns and considerations. One such concern is that older machinery might be less energy-efficient compared to newer models, potentially leading to higher operational energy consumption. Additionally, the Indian government has, at times, considered imposing bans or restrictions on the import of older used machinery with the aim of protecting domestic manufacturing industries and ensuring a higher standard of quality in the equipment used. For instance, there have been discussions about potentially restricting the import of used machinery that is more than five years old. Therefore, it is essential for importers to strike a balance between the clear economic advantages of used machinery and the potential environmental and quality considerations, as well as being aware of any evolving government regulations in this area. The long-term sustainability of importing and using second-hand industrial equipment in India will likely depend on carefully navigating this balance between economic viability, environmental responsibility, and compliance with the prevailing regulatory landscape.

8. The Role of Online Marketplaces:

8.1. Facilitating International Trade:

Online marketplaces have emerged as pivotal platforms in facilitating international trade, particularly in the buying and selling of used industrial machinery. These digital platforms effectively connect international sellers with Indian buyers, streamlining the process of sourcing equipment across geographical boundaries. These platforms offer unparalleled accessibility and a wide reach, enabling buyers in India to explore a vast selection of used machinery available from sellers around the globe. Keyleerkart stands as a prominent example of an online marketplace specifically catering to the Indian market for used industrial machinery. In essence, online marketplaces have become indispensable tools for Indian buyers seeking to tap into the global market for pre-owned industrial equipment, offering remarkable convenience and a significantly expanded range of choices. These digital platforms simplify the often complex process of finding and comparing machinery from various sellers and locations, thereby substantially reducing the time and effort traditionally required for equipment sourcing.

8.2. Key Platforms for Indian Buyers and Dealers:

Indian buyers and dealers interested in the trade of used industrial machinery have access to a diverse range of online marketplaces, both international and domestic. Prominent international platforms that list a wide selection of used machinery include Machinery Trader, Equipment Trader, IronPlanet, Mascus, Exapro, MachineSeeker, Surplus Record, and EquipNet. Within India, several online marketplaces specifically cater to the needs of local buyers and sellers, such as Keyleerkart, Zatpat Machines, Rao's Machines, and MSME Mart. Additionally, general e-commerce websites like eBay Industrial and global sourcing platforms like Alibaba also feature listings for used industrial machinery. The availability of this extensive network of online platforms provides Indian buyers and dealers with numerous avenues to facilitate the trade of second-hand industrial equipment. The optimal choice of platform often depends on factors such as the specific type of machinery being sought or offered, the desired geographical reach, and the particular needs and preferences of the buyer or seller.

8.3. Benefits and Considerations of Using Online Platforms:

Utilizing online marketplaces for the trade of used industrial machinery offers a multitude of benefits. These include access to a wide selection of equipment from various sellers, often at competitive prices, as well as the ease of comparing specifications and prices across different listings. These platforms also facilitate direct communication between buyers and sellers, enabling them to clarify details and negotiate terms. However, it is important for buyers to be aware of certain considerations when using online marketplaces, particularly in international transactions. Conducting thorough due diligence on sellers and the listed machinery is crucial, as physical inspection can sometimes be challenging. Additionally, international transactions may involve complexities related to shipping, customs procedures, and payment security. It is advisable for buyers to utilize platforms that offer secure payment methods and some form of buyer protection policies to mitigate potential risks. While online marketplaces provide numerous advantages in terms of convenience and selection, buyers must exercise caution and conduct comprehensive research before committing to a purchase, especially when dealing with sellers located in different countries. Relying solely on online listings without proper verification and inspection can expose buyers to risks, and therefore, considering the use of escrow services or other secure payment mechanisms is often a prudent approach.

9. Lifespan, Maintenance, and Long-Term Ownership:

9.1. Typical Lifespan of Industrial Machinery:

The expected lifespan of industrial machinery, particularly CNC machines, can vary depending on several factors, including the type of machine, the quality of its construction, the intensity of its usage, and the diligence of its maintenance. Generally, a well-maintained CNC machine can have a service life ranging from 10 to 20 years or even longer. In some cases, with exceptional care and proactive maintenance, CNC machines have been known to remain operational for over 30 years. Similarly, robotic arms are designed for longevity and can also have a long service life. For instance, FANUC robots, when properly maintained, can last for many years, even decades, with a typical life expectancy falling within the range of 80,000 to 100,000 hours of operation. Injection molding robot arms typically have a service life that ranges from 8 to 15 years, depending on factors such as the quality of their components, the frequency of their operation, and the effectiveness of their maintenance. This indicates that used industrial machinery, if it has been well-maintained throughout its operational history, can still offer a significant remaining lifespan, potentially providing a substantial return on investment for businesses in India. The key determinant of the longevity of used equipment is often the quality of its original build and the consistency and thoroughness of its past maintenance practices.

9.2. Maintenance Considerations for Used Machinery:

To maximize the lifespan and ensure the continued performance of imported used industrial machinery, establishing a robust maintenance schedule is of paramount importance. For used lathes, essential maintenance considerations include regular cleaning to remove debris and chips, consistent lubrication of all moving parts, periodic checks and adjustments of alignment, ensuring proper belt tension, and maintaining the cutting tools in good condition. Lubrication is often described as the lifeblood of a machine, highlighting its critical role in preventing wear and tear. Robotic arms also require a structured maintenance plan, which typically involves weekly visual inspections, monthly checks of components and connections, quarterly in-depth servicing, and comprehensive annual overhauls. For CNC machines, extending their lifespan involves proper operation within their recommended parameters, adhering to a regular maintenance schedule that includes lubrication, cleaning, and timely replacement of worn parts, and addressing any operational issues promptly. Heat treatment furnaces necessitate a preventative maintenance plan that includes regular inspections of critical components such as burners, insulation, wiring, and safety systems to ensure efficient and safe operation. By diligently following a comprehensive maintenance schedule tailored to the specific type of machinery, Indian businesses can significantly extend the operational life of their imported used equipment and ensure its continued productivity, ultimately contributing to better long-term value and minimizing the risk of costly unexpected breakdowns.

9.3. Long-Term Ownership Guidance:

Successful long-term ownership of imported used industrial machinery requires proactive planning and a commitment to ongoing care. Sourcing spare parts from reliable suppliers is crucial to minimize downtime in case of component failures. Investing in training for machine operators on proper usage techniques and basic maintenance procedures is also essential, as this can help prevent damage and ensure the equipment is operated within its design limits. It is also advisable to consider engaging professional inspection and maintenance services periodically, especially for more complex machinery like CNC machines and robotic arms, to ensure thorough checks and timely interventions. Furthermore, as technology evolves, businesses might consider potential upgrades or retrofits to their used machinery to improve its efficiency, enhance its capabilities, or meet new production requirements. By proactively addressing these aspects of long-term ownership, Indian businesses can ensure the continued productivity and cost-effectiveness of their investments in imported used industrial equipment, minimizing downtime and maximizing the return on their capital.

10. Conclusion and Recommendations:

The import of second-hand industrial machinery into India presents a compelling proposition for Indian buyers, offering significant economic advantages through reduced acquisition costs and access to a wide range of equipment from the global market. However, this opportunity is accompanied by the need to navigate regulatory complexities, ensure the quality and reliability of used equipment, and plan for long-term ownership through effective maintenance practices. The Indian market demonstrates a growing demand for used machinery across key sectors like automotive, electronics, and manufacturing, particularly for equipment such as CNC machines and robotic arms. Online marketplaces play a crucial role in connecting international sellers with Indian buyers, providing a platform for discovery and trade. Furthermore, utilizing refurbished machinery aligns with the increasing global emphasis on sustainability and the principles of a circular economy.

For Indian buyers considering importing second-hand industrial machinery, it is recommended to conduct thorough research on market prices and the applicable import regulations. Prioritizing quality and reliability through detailed pre-purchase inspections, potentially involving Chartered Engineers, is essential. Buyers should also meticulously factor in all associated costs, including shipping, installation, and potential future maintenance and repairs, to accurately assess the overall value. Engaging with reputable platforms like Keyleerkart can provide access to a curated selection of used machinery and facilitate a smoother transaction process. Finally, establishing a robust maintenance plan from the outset is crucial for ensuring the long-term performance and maximizing the lifespan of the imported equipment.

For machinery dealers looking to capitalize on this growing market, focusing on sourcing high-quality used machinery from reliable international markets is key. Providing detailed and transparent inspection reports to potential buyers can build trust and facilitate sales. Offering value-added services such as installation support and maintenance guidance can further enhance their appeal to Indian businesses. Leveraging online marketplaces, including India-specific platforms like Keyleerkart, is vital for reaching a broad audience of potential buyers across India.

In conclusion, the import of second-hand industrial machinery offers significant opportunities for the growth and development of the manufacturing sector in India. By carefully navigating the associated complexities and adopting best practices in sourcing, inspection, and maintenance, Indian buyers and dealers can effectively leverage this global market to their advantage, with platforms like Keyleerkart playing a pivotal role in facilitating this continued growth.

Table 1: Cost Comparison: New vs. Used Industrial Machinery (USD)

| Machinery Type | New Machine Price Range (USD) | Used Machine Price Range (USD) | Potential Savings (USD) | Source Snippet IDs |

|---|---|---|---|---|

| CNC Milling Machines | 10,000 - 500,000 | 2,000 - 100,000+ | 8,000 - 400,000+ | |

| CNC Lathe Machines | 10,000 - 500,000 | 8,000 - 100,000+ | 2,000 - 400,000+ | |

| CNC Router Machines | 1,000 - 200,000+ | 2,000 - 75,000+ | -1,000 - 125,000+ | |

| Robotic Arms | 20,000 - 100,000+ | 10,000 - 50,000+ | 10,000 - 50,000+ | |

| Heat Treatment Machines | - | - | - | - |