In the fast-paced world of manufacturing and automation, technology is constantly evolving. New machinery is being designed with advanced features like IoT connectivity, real-time data tracking, and AI-driven controls. But what happens to older, perfectly functional machines that lack these bells and whistles? Are they destined to become obsolete?

Not quite.

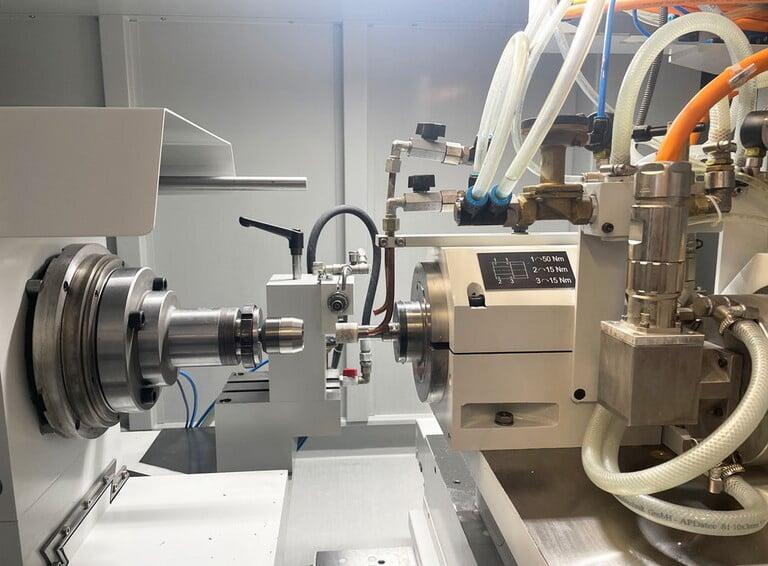

Thanks to retrofitting, older machines—especially high-quality pre-owned German equipment—can be upgraded to perform just as efficiently as modern ones, without the massive price tag. Retrofitting offers manufacturers a powerful way to extend the life, boost the performance, and increase the intelligence of existing machinery. At KeyLeer Kart, we help Indian companies tap into this opportunity to unlock more value from their used equipment and stay competitive in an increasingly smart manufacturing landscape.

What Is Retrofitting?

Retrofitting refers to the process of adding new technology or features to older machines, essentially modernizing them without replacing them entirely. This can include adding:

PLC (Programmable Logic Controllers)

HMI (Human-Machine Interfaces)

Sensors and Smart Modules

Automation Systems

Remote Monitoring and Diagnostics

Energy-efficient components

With retrofitting, machines that were once purely mechanical can now operate with digital intelligence, allowing for better control, reduced downtime, predictive maintenance, and improved safety.

Why Retrofitting Makes Sense for Used German Machines

German machinery is globally respected for its engineering precision, durability, and robust mechanical structure. Even after years of use, many of these machines are mechanically sound, offering a solid foundation for a smart upgrade. By retrofitting these machines, Indian manufacturers can enjoy the best of both worlds: German engineering and modern automation, all without the cost of new machinery.

At KeyLeer Kart, we specialize in sourcing second-hand machines from Germany that are ideal candidates for retrofitting. Our team, in collaboration with our partners, can recommend or facilitate upgrades that align with your production goals, whether it’s improving throughput, reducing energy consumption, or enabling real-time monitoring across your plant.

Benefits of Retrofitting Old Equipment

Retrofitting has become a strategic tool for Indian businesses that want to innovate while staying lean. Here's why it's gaining traction:

✅ Cost-Effective: Upgrading an old machine can cost significantly less than purchasing a new one.

⚙️ Improved Efficiency: Modern controls and automation features can increase productivity and reduce operational bottlenecks.

📊 Data-Driven Decisions: Retrofitted machines can provide live data on performance, helping operators make smarter decisions.

🔧 Minimized Downtime: Predictive maintenance features help avoid unexpected breakdowns.

🌱 Sustainable Manufacturing: Extending the life of machines reduces industrial waste and carbon footprint.

🚀 Quick Integration: Retrofitting usually takes less time than ordering, installing, and setting up a new machine.

Who Can Benefit the Most?

Retrofitting is ideal for emerging manufacturing companies, mid-size factories, and OEMs who want to scale smartly without overspending. It’s especially useful in sectors like:

Food & Beverage Packaging

Pharmaceuticals

Metalworking

Automotive Components

Textile & Printing

Plastic & Polymer Processing

If your production relies on tried-and-tested machines that are mechanically strong but technologically outdated, retrofitting can help you modernize operations without disrupting your cash flow.

How KeyLeer Kart Supports Retrofitting in India

At KeyLeer Kart, we don’t just deliver used machines—we help our clients future-proof their investment. Along with our trusted German and Indian partners, we provide consultation and support for retrofitting services. Whether you’re looking to automate packaging lines, install smart monitoring sensors, or integrate your machines with Industry 4.0 systems, we’ll guide you through it.

Our approach is personalized. We evaluate your machinery, suggest retrofit modules or upgrades, and connect you with technicians or engineers who can carry out the work efficiently. We aim to make second-hand machinery not just a smart buy—but a smarter machine for your factory floor.

Final Thoughts: Smarter, Not Just Cheaper

Investing in second-hand equipment no longer means compromising on innovation. With retrofitting, Indian manufacturers can bring aging machines into the digital age—boosting productivity, reducing costs, and staying agile in a competitive market. Whether you're just starting out or expanding your operations, retrofitting your equipment can be the key to unlocking a new level of efficiency.

Want to explore high-quality German machinery that’s perfect for retrofitting? Visit or reach out to our team for a free consultation. Let’s turn your factory into a smart factory—one machine at a time.