Why They’re a Smart Long-Term Investment

Why They’re a Smart Long-Term Investment

In today's fast-paced industrial world, staying competitive requires businesses to embrace innovation and efficiency. Robotic arms, a cornerstone of modern automation, have become indispensable across various sectors. From automotive manufacturing to electronics assembly, these advanced machines are revolutionizing production processes, offering unmatched precision, scalability, and cost efficiency. For businesses considering an upgrade to their manufacturing lines, investing in robotic arms is not just a technological leap but also a strategic move for long-term returns.

What Makes Robotic Arms Essential in Production?

Unmatched Precision and Accuracy

Robotic arms are engineered to perform repetitive tasks with exceptional accuracy. Unlike human labor, these machines maintain consistency, ensuring high-quality output and minimizing errors. This precision is particularly vital in industries like electronics, where minute errors can lead to significant defects.

Enhanced Productivity

Robotic arms can operate 24/7 without breaks, drastically boosting production rates. With these machines in place, manufacturers can meet tight deadlines and scale up production during peak demand without compromising quality.

Versatility in Applications

Modern robotic arms come with flexible configurations and programmable functions, enabling them to handle a variety of tasks, from welding and material handling to packaging and assembly. Their adaptability makes them suitable for diverse industries, including automotive, pharmaceuticals, and food processing.

Safety and Risk Mitigation

In hazardous work environments, robotic arms protect human workers by taking over dangerous tasks. This reduces workplace accidents and ensures compliance with safety standards, creating a safer work environment.

Unmatched Precision and Accuracy

Robotic arms are engineered to perform repetitive tasks with exceptional accuracy. Unlike human labor, these machines maintain consistency, ensuring high-quality output and minimizing errors. This precision is particularly vital in industries like electronics, where minute errors can lead to significant defects.Enhanced Productivity

Robotic arms can operate 24/7 without breaks, drastically boosting production rates. With these machines in place, manufacturers can meet tight deadlines and scale up production during peak demand without compromising quality.Versatility in Applications

Modern robotic arms come with flexible configurations and programmable functions, enabling them to handle a variety of tasks, from welding and material handling to packaging and assembly. Their adaptability makes them suitable for diverse industries, including automotive, pharmaceuticals, and food processing.Safety and Risk Mitigation

In hazardous work environments, robotic arms protect human workers by taking over dangerous tasks. This reduces workplace accidents and ensures compliance with safety standards, creating a safer work environment.

Why Are Robotic Arms a Good Investment for Long-Term Returns?

Reduced Operational Costs

While the initial investment in robotic arms might seem significant, they help cut long-term costs by reducing dependency on human labor, minimizing waste, and streamlining production. Over time, the savings on wages, training, and operational inefficiencies far outweigh the upfront costs.

Scalability for Future Needs

Robotic arms are designed to grow with your business. As your production demands increase, you can upgrade or reprogram these machines to handle new tasks. This scalability ensures that your investment remains relevant and valuable for years.

Improved Quality Assurance

By maintaining consistent performance, robotic arms enhance the overall quality of products. This leads to increased customer satisfaction, fewer returns, and a stronger brand reputation — all contributing to long-term profitability.

Faster ROI

Industries adopting robotic arms often report a quicker return on investment (ROI). With increased production capacity and reduced operational costs, businesses can recover their investment sooner and enjoy sustained financial benefits.

Alignment with Industry 4.0

As industries move towards digital transformation, integrating robotic arms ensures your business remains at the forefront of Industry 4.0. The automation and data-driven insights provided by robotic systems pave the way for smarter, more efficient production lines.

Reduced Operational Costs

While the initial investment in robotic arms might seem significant, they help cut long-term costs by reducing dependency on human labor, minimizing waste, and streamlining production. Over time, the savings on wages, training, and operational inefficiencies far outweigh the upfront costs.Scalability for Future Needs

Robotic arms are designed to grow with your business. As your production demands increase, you can upgrade or reprogram these machines to handle new tasks. This scalability ensures that your investment remains relevant and valuable for years.Improved Quality Assurance

By maintaining consistent performance, robotic arms enhance the overall quality of products. This leads to increased customer satisfaction, fewer returns, and a stronger brand reputation — all contributing to long-term profitability.Faster ROI

Industries adopting robotic arms often report a quicker return on investment (ROI). With increased production capacity and reduced operational costs, businesses can recover their investment sooner and enjoy sustained financial benefits.Alignment with Industry 4.0

As industries move towards digital transformation, integrating robotic arms ensures your business remains at the forefront of Industry 4.0. The automation and data-driven insights provided by robotic systems pave the way for smarter, more efficient production lines.

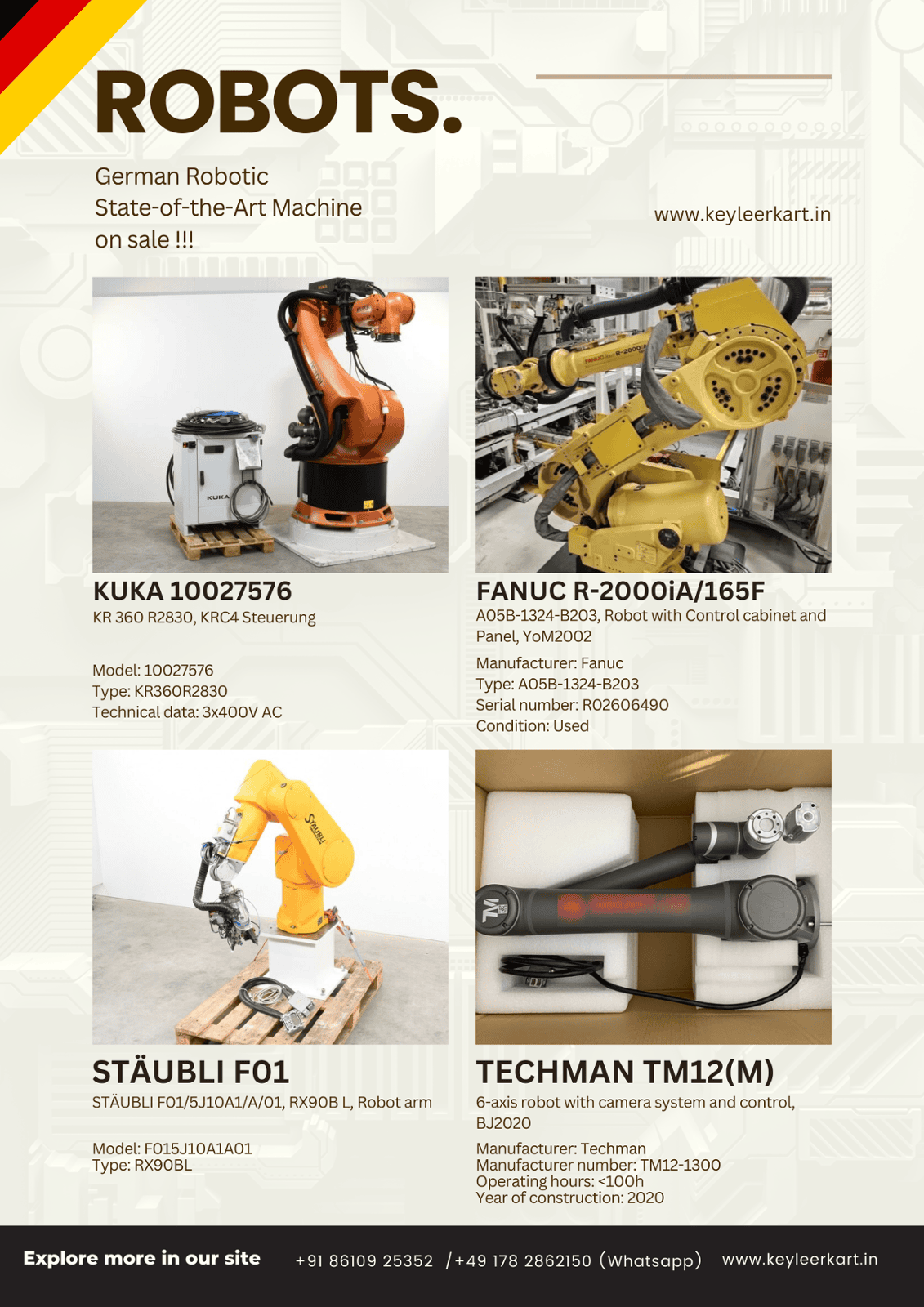

KeyLeer Kart: Your Partner in Advanced Automation

At KeyLeer Kart, we understand the transformative potential of robotic arms in modern manufacturing. We offer a wide range of automation solutions tailored to meet the specific needs of your business. Whether you’re in the market for new or refurbished robotic arms, we ensure quality, reliability, and cost-effectiveness.

Our commitment to sourcing high-quality automation equipment empowers businesses to optimize production, reduce costs, and stay competitive in an ever-evolving market.

At KeyLeer Kart, we understand the transformative potential of robotic arms in modern manufacturing. We offer a wide range of automation solutions tailored to meet the specific needs of your business. Whether you’re in the market for new or refurbished robotic arms, we ensure quality, reliability, and cost-effectiveness.

Our commitment to sourcing high-quality automation equipment empowers businesses to optimize production, reduce costs, and stay competitive in an ever-evolving market.

Conclusion

Robotic arms are not just a luxury but a necessity for manufacturers aiming to thrive in the competitive industrial landscape. Their precision, scalability, and cost-efficiency make them a smart investment for businesses of all sizes. By integrating robotic arms into your production line, you’re not just embracing modern technology — you’re securing a future of growth and profitability.

KeyLeer Kart is here to help you make that leap. Invest today and position your business for success in the era of automation!

Robotic arms are not just a luxury but a necessity for manufacturers aiming to thrive in the competitive industrial landscape. Their precision, scalability, and cost-efficiency make them a smart investment for businesses of all sizes. By integrating robotic arms into your production line, you’re not just embracing modern technology — you’re securing a future of growth and profitability.

KeyLeer Kart is here to help you make that leap. Invest today and position your business for success in the era of automation!