A Comprehensive Guide

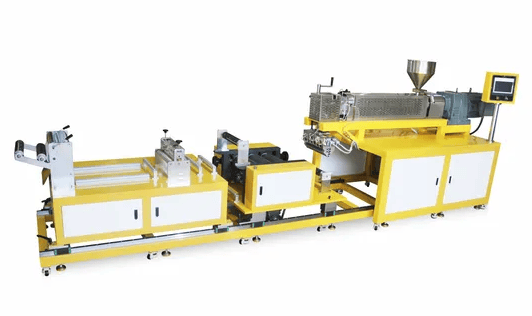

Granule Making

Granule-making machines are used in various industries to convert raw materials into small granular particles. The process may vary depending on the type of material (plastic, metal, or food) and the machine used. Granules are essential components in manufacturing processes for various products.

Our Expertise in Granule Making:

- Machine Type: Extruder

- Brands: Buss, Thyssen, Bhuller

PET FILM

PET (Polyethylene Terephthalate) film-making machines are specialized equipment used to produce high-quality PET films, which are used in various applications such as packaging, electronics, and labeling. The process typically involves extrusion, cooling, and winding.

Machine- PET Line

Brands- Bruckner, Donear

BOPP FILM

BOPP FILM

BOPP (Biaxially Oriented Polypropylene) film-making machines produce BOPP films, which are widely used in packaging, labeling, and various other applications due to their excellent clarity, strength, and barrier properties. The process involves several stages, including extrusion, biaxial orientation, and winding.

Brands- Bruckner, Donear

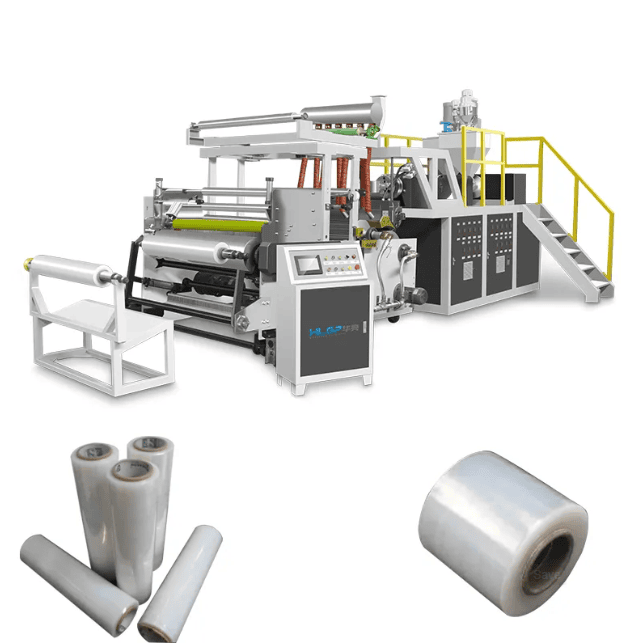

CPP FILM

CPP FILM

CPP (Cast Polypropylene) film-making machines are used to produce CPP films, which are known for their excellent clarity, strength, and sealability. CPP films are commonly used in food packaging, medical applications, and various other uses. The process involves extrusion, casting, and winding.

Machine- Cast Extruder

Brands- Reifenhauser

POLYETHYLENE

POLYETHYLENE

Polyethylene (often abbreviated as PE) film-making machines are used to produce polyethylene films, which are widely used in packaging, agriculture, and various other applications. Polyethylene films can be made using different types of machines depending on the desired film properties and applications, including blown film and cast film processes.

Machine- Blown Film line

Brands- Reifenhauser, W&H, Macchi, Alpine, Bandera

ALUMINIUM FOIL

ALUMINIUM FOIL

Aluminum foil is a versatile material widely used in packaging, insulation, and various industrial applications due to its barrier properties, malleability, and durability. The production of aluminum foil involves several key steps, from refining aluminum ore to rolling it into thin sheets.

Machine- Rolling

Brands- Achenburg

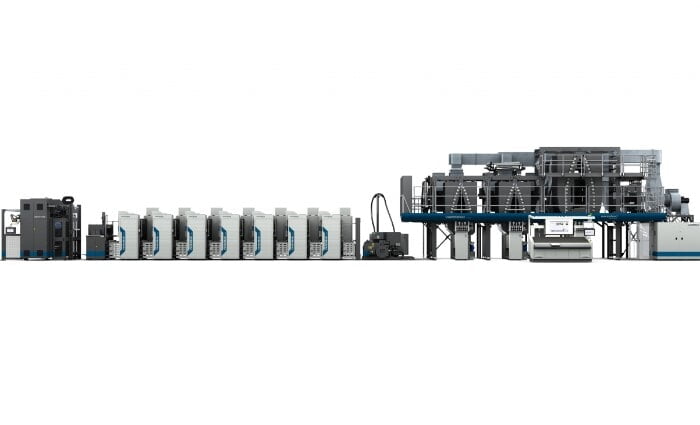

PRINTING

PRINTING

Printing processes in packaging machinery are essential for applying designs, text, and other information to packaging materials such as films, labels, boxes, and containers. The choice of printing technology depends on the type of packaging material, the complexity of the design, and production requirements.

Machine- Roto Gravure

Brands- Bobst , Rotomec, SAM, Sungan, Cerutti, W & H, Uteco

Machine- CI Flexo

Brands- W & H, Comexi, Uteco, Soma, KYMC, F & K

Machine- Narow Web

Brands- Bobst, Neilpeter, Gallas

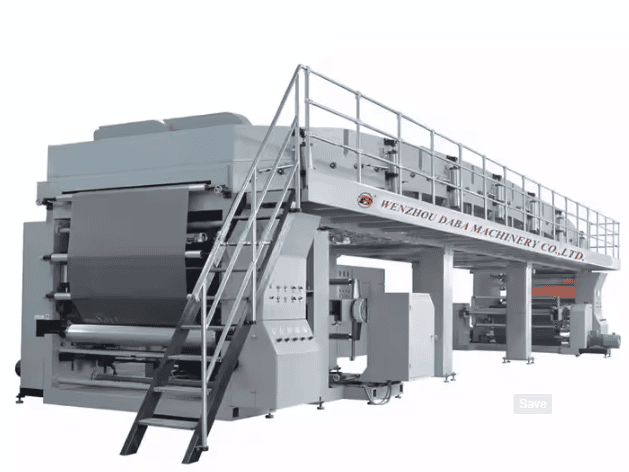

LAMINATION

LAMINATION

Lamination in packaging is a process where multiple layers of materials are bonded together to create a single composite structure. This enhances the properties of the packaging material, such as its strength, barrier properties, or appearance. Lamination is commonly used to improve durability, protect against moisture, enhance visual appeal, and extend shelf life.

Machine- Extrussion Lamination

Brands- Davis Standard, Bobst, Daekwand, ETS, Fongee, Sam, Sungan

Machine- Solventbase Lamination

Brands- Bobst, Nordmecanica, Comexi, Soma Engineering, Schiavi

Machine- Solventless Lamination

Brands- Bobst, Nordmecanica, Comexi, Soma Engineering, SchiavBrands- Bobst, Nordmecanica, Comexi, Soma Engineering, Schiavi

Machine- Coating Machines

Brands- Kronnet, Olbrich, Polytype, Bobst, Nordnecanica, Sam, Sungan, Cotema

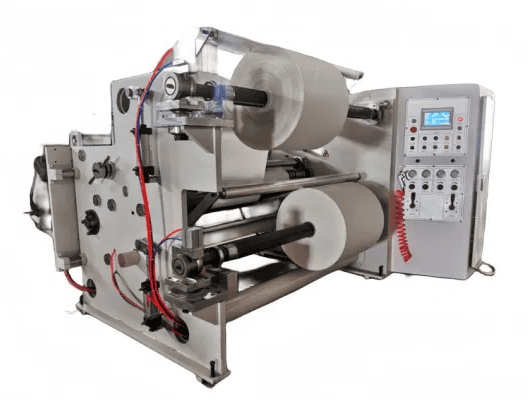

SITTERS

SITTERS

It seems like you might be referring to "slitters" in the context of packaging machinery. Slitters are used to cut large rolls of material, such as paper, film, or foil, into narrower rolls or sheets. This process is crucial for producing packaging materials in the specific widths and dimensions required for various applications.

Machine- Primary Slitter

Brands- Jkampf, Atlas, Titan, Globbel IMS

Machine- Secondry Slitter Jkampf

Brands- Atlas, Titan, Globbel IMS

POUCHING

POUCHING

The pouching process in packaging machinery involves converting flexible packaging materials into pouches or bags used for a variety of products, from food and beverages to pharmaceuticals and consumer goods. Pouching machines are designed to efficiently form, fill, and seal pouches in a streamlined, automated manner.

Machine- Pouching Machines

Brands- Totani, Waterline, Nichebe

VACUM METALIZER

VACUM METALIZER

Vacuum metallization is a process used in packaging to apply a thin layer of metal, typically aluminum, onto various substrates. This process enhances the appearance, barrier properties, and functionality of packaging materials. It's widely used in creating reflective and protective surfaces on films for food packaging, decorative items, and more.

Machine- Metallizer

Brands- General Metalizer, Leybold

- The packaging machinery process is a complex and multi-faceted operation that involves precise coordination and control of various steps.

- From material preparation and pouch formation to filling, sealing, and quality control, each stage plays a crucial role in ensuring that the final product is safely and attractively packaged.

- By understanding the intricacies of this process, manufacturers can optimize their operations, enhance product quality, and meet consumer demands more effectively.