Increase throughput and reduce downtime

Improve precision and product quality

Lower operational cost per unit by using automation or more efficient machines

Stay competitive as global supply-chains demand tighter tolerances and faster delivery

Why the “Industrial Machinery” Market is a Strategic Must-Explore

In today’s manufacturing landscape in India, upgrading equipment isn’t optional — it’s essential. Whether you’re in automotive, electronics, metal-fabrication, or general manufacturing, the right machinery helps you:

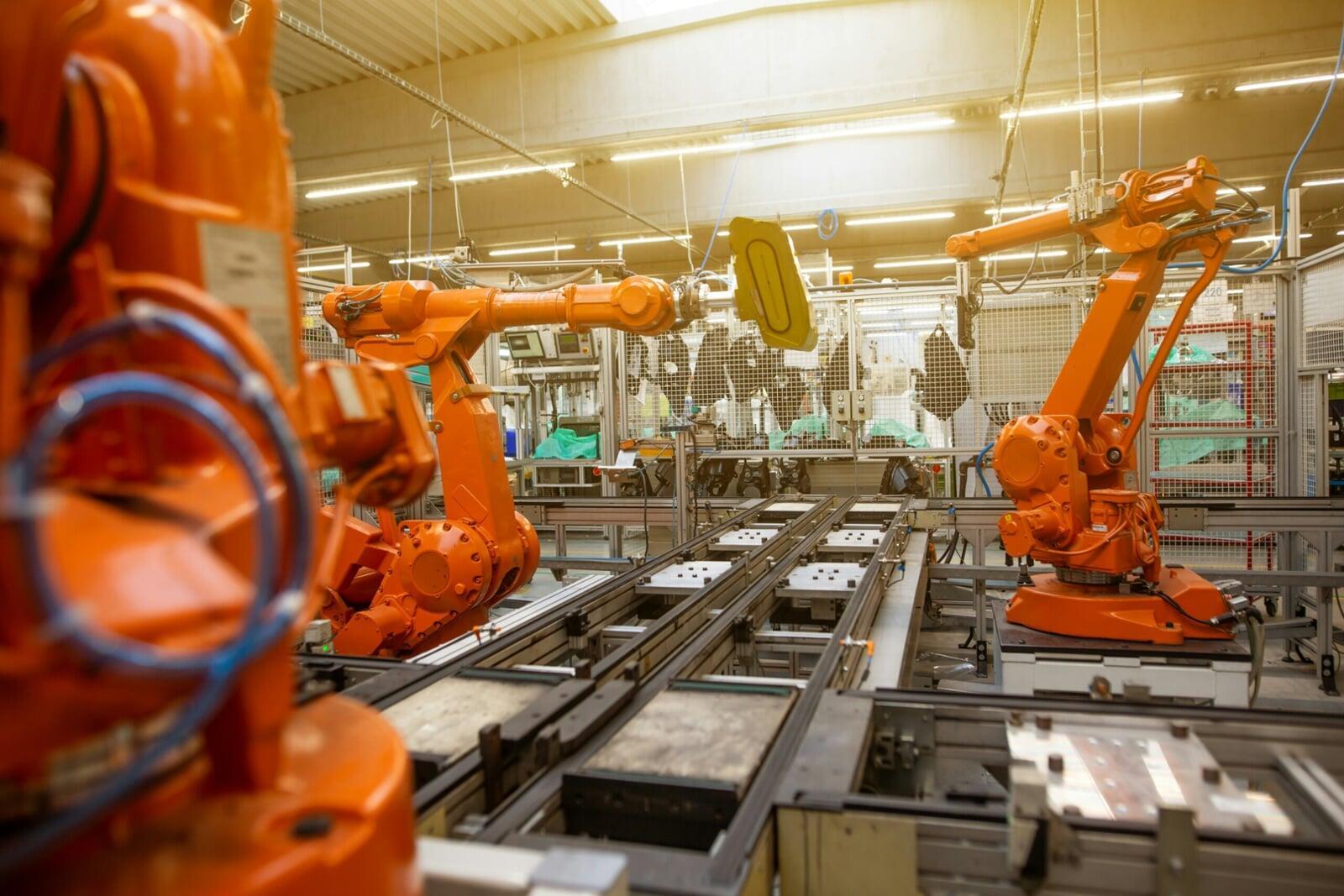

The “Industrial Machinery” category on your site offers a wide range of equipment—from CNC machining centres and hydraulic presses to inspection systems and automation peripherals. This diversity means there’s an opportunity whether you’re scaling up, retrofitting, or optimising an existing line.

In today’s manufacturing landscape in India, upgrading equipment isn’t optional — it’s essential. Whether you’re in automotive, electronics, metal-fabrication, or general manufacturing, the right machinery helps you:

The “Industrial Machinery” category on your site offers a wide range of equipment—from CNC machining centres and hydraulic presses to inspection systems and automation peripherals. This diversity means there’s an opportunity whether you’re scaling up, retrofitting, or optimising an existing line.

What to Look For: Key Criteria Before You Buy

When browsing listings in the industrial-machinery category, keep these attributes in mind to ensure you make a confident purchase:

1. Machine Condition & History

How many operating hours or cycles has the equipment logged?

Is there a service/maintenance record?

Has any major component been replaced (motors, hydraulics, control systems)?

2. Specification Alignment

Does the machine’s capacity, size, payload, axis configuration or power requirements match your production need?

Will it integrate into your plant (floor space, foundation, power supply, connectivity)?

3. Support & Spare Parts

Especially in used equipment, ensure spare parts are still available (motors, drives, controllers, hydraulics).

Local agent or after-sales support is a big plus (for India context).

4. Total Cost of Ownership

Consider not just the purchase price, but installation, commissioning, training, transport, customs (if imported), and any retrofit required.

A used high-quality machine might cost less over lifetime than a new mid-range unit.

5. Future-Proofing

Does the machine allow for upgrades (automation, IoT/Industry 4.0 connectivity, additional axes)?

Is the manufacturer or model widely used so you’re not locked into niche parts?

Smart Use-Cases: How Machines Drive Real Value

Here are some typical situations where companies are seeing strong returns from investing in the right machinery:

A metal fabrication shop brings in a used hydraulic press to increase forming capacity and reduce manual labour.

An electronics assembly unit upgrades to a high-performance inspection or automation machine to reduce rejects and improve first-pass yield.

A component manufacturer adds automation (robotic pick-&-place, CNC machine) to a line previously done manually—boosting speed and lowering workforce constraints.

Why the Listing Platform Makes Sense for You

Your industrial-machinery category acts as a curated marketplace where you can compare models, manufacturers, and price-points—all in one place. You benefit from:

- A broad selection of machinery across types and use-cases

- The ability to filter by manufacturer, year of manufacture, condition, region

- Access to global-class equipment sourced for Indian manufacturing conditions

Final Takeaway

Whether you’re investing in a brand-new CNC centre or selecting a high-quality used machine, the key is to match your production need with the machine’s spec and service readiness. Use the machinery marketplace as a strategic tool—not just to buy a machine, but to elevate your manufacturing capability.

Whether you’re investing in a brand-new CNC centre or selecting a high-quality used machine, the key is to match your production need with the machine’s spec and service readiness. Use the machinery marketplace as a strategic tool—not just to buy a machine, but to elevate your manufacturing capability.