Production Line 1: Large Motor Rotor & Stator Core Manufacturing

- Purpose: Manufacturing rotor and stator cores for large electric motors

- Frame Sizes: 280-355

- Power Capacities: 75-355 kW

- Purpose: Manufacturing rotor and stator cores for large electric motors

- Frame Sizes: 280-355

- Power Capacities: 75-355 kW

Key Equipment:

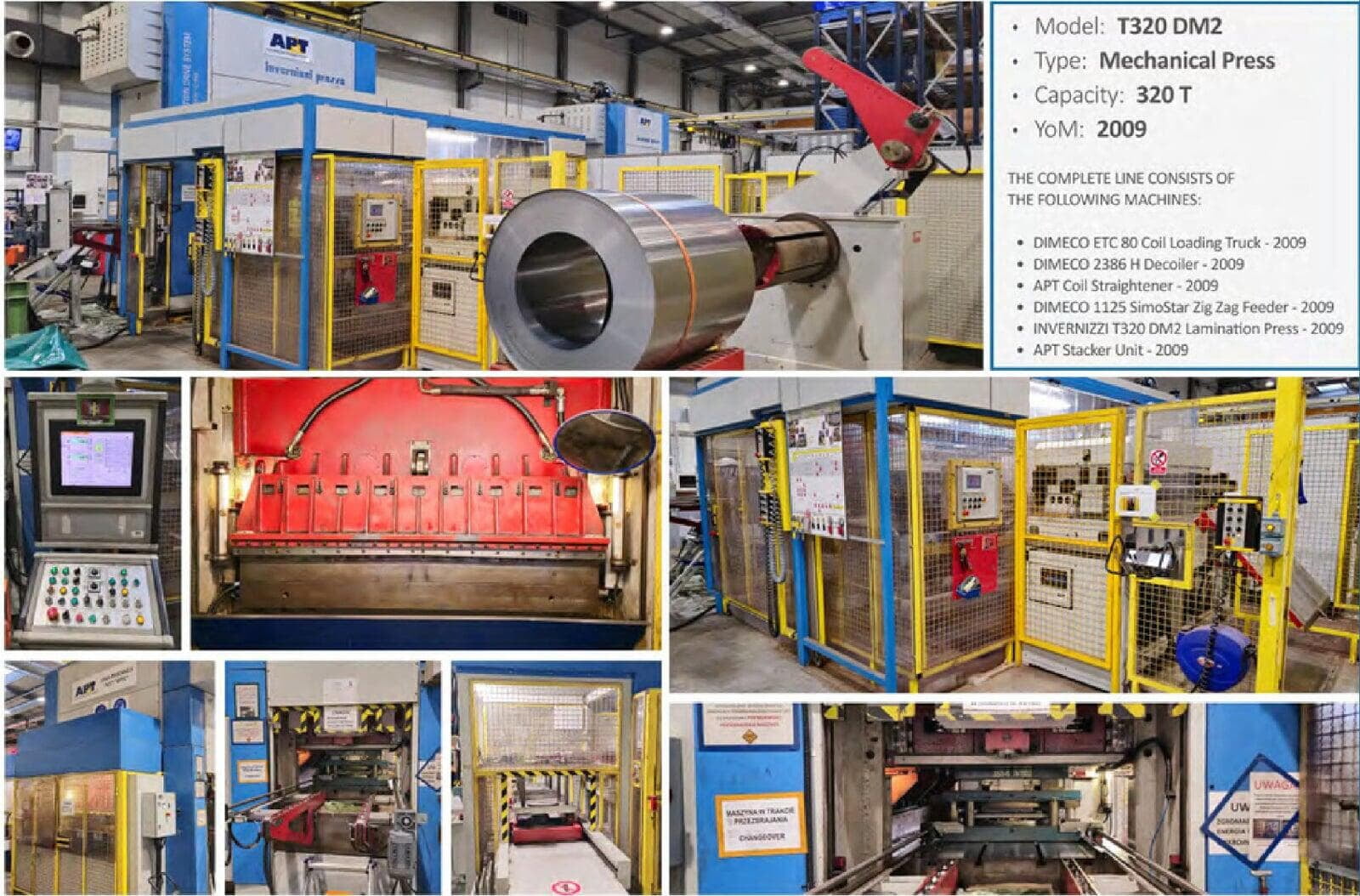

1. INVERNIZZI Lamination Press Lines (APT1 & APT2) – Installed in 2009

- DIMECO ETC 80 Coil Loading Truck – 2009

- DIMECO 2386 H Decoiler – 2009

- APT Coil Straightener – 2009

- DIMECO 1125 SimoStar Zig Zag Feeder – 2009

- INVERNIZZI T320 DM2 Lamination Press – 2009

- APT Stacker Unit – 2009

- APT Destacking Unit – 2009

- INVERNIZZI T250 DM2 Lamination Press – 2009

- APT Restacking Unit for Rotor Sheet – 2009

- APT Restacking Unit for Stator Sheet – 2009

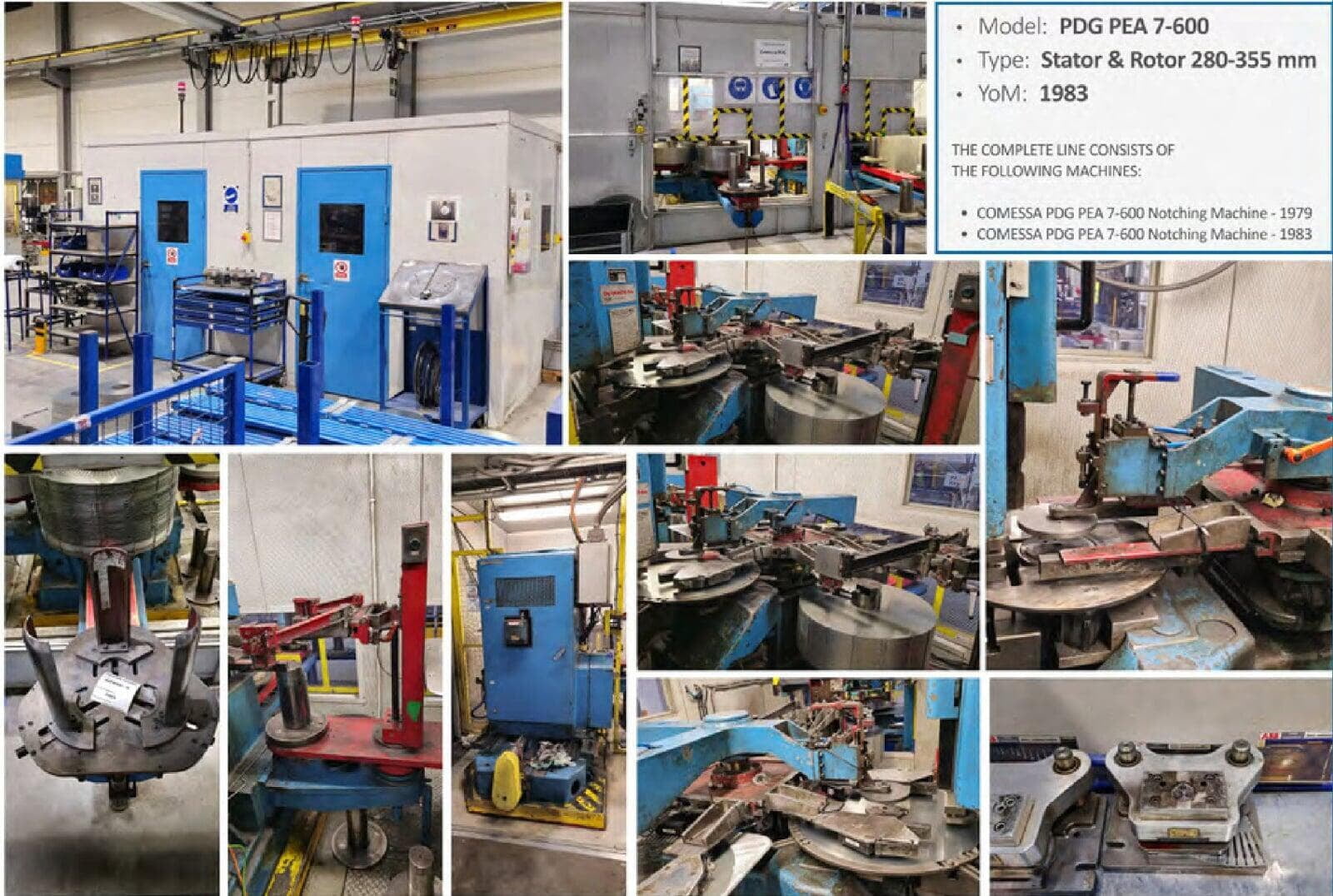

2. COMESSA Notching Press Cell – Installed in 1983

- COMESSA POG PEA 7-600 Notching Machine – 1979

- COMESSA POG PEA 7-600 Notching Machine – 1983

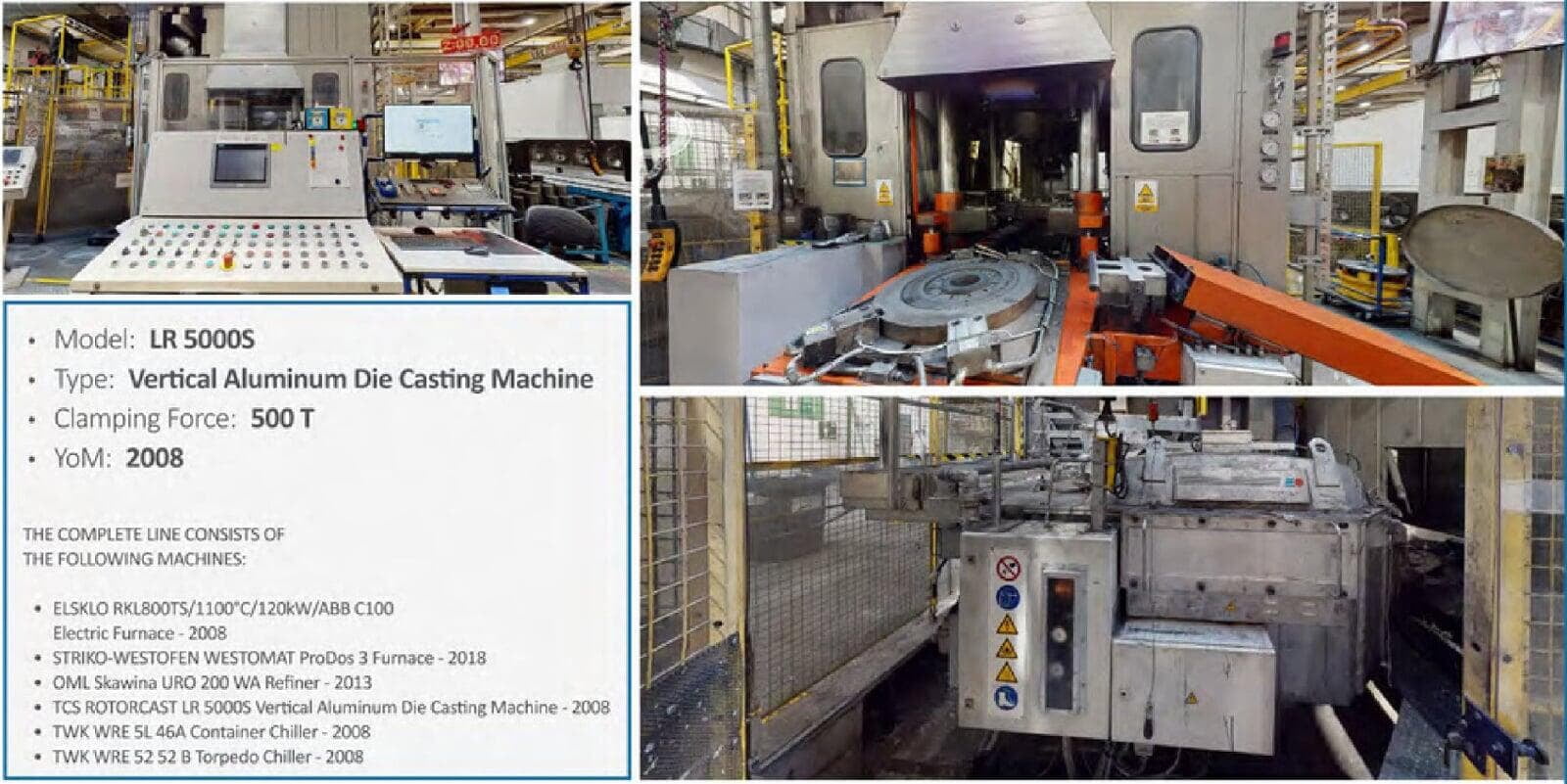

3. TCS Rotor Die Casting Cell – Installed in 2008

- ELSKLO RKLBOOTS/1100°C/120RW/ABB C100 Electric Furnace – 2008

- STRIKO-WESTOFEN WESTOMAT ProDos 3 Furnace – 2018

- OML Skawina URO 200 WA Refiner – 2013

- TCS ROTORCAST UR 50005 Vertical Aluminum Die Casting Machine – 2008

- TWK WRE 51 464 Container Chiller – 2008

- TWE WRE 52 52 B. Torpedo Chiller – 2008

Capabilities:

Production Line 2: Mid-Range Motor Rotor & Stator Manufacturing Setup

Purpose: Producing rotor and stator cores for mid-range electric motors

- Frame Sizes: 160-250

- Power Capacities: 11-55 kW

Purpose: Producing rotor and stator cores for mid-range electric motors

- Frame Sizes: 160-250

- Power Capacities: 11-55 kW

Key Equipment:

Key Equipment:

1. SCHULER High-speed Lamination Press Line – Installed in 2014

- SCHULER SAL400 Lamination Press – 2014

- ALTEK Coll Turner with Roller Track – 2015

- SARONNI AD4/C-R28/500 Deceleration – 2013

- SARONNI Straightener – 2014

- SCHULER Feedmax 630 Feeder – 2014

- ASTOS DM225 Scrap Conveyor – 2019

2. DEMA Stator Welding Cell – Installed in 2018

- ABB IR8 6700 Sheet Handling Robot – 2018

- BIMAC DEMA 2 Sheet Palletizer – 2018

- DEMA Welding Unit on Turning Table – 2018

- WHITBY SIMI-15V Multi Slot Insulation – 2001

- ABB IRB 7000 Stator Core Handling Robot – 2018

- DEMA Stator Core Palletizer – 2018

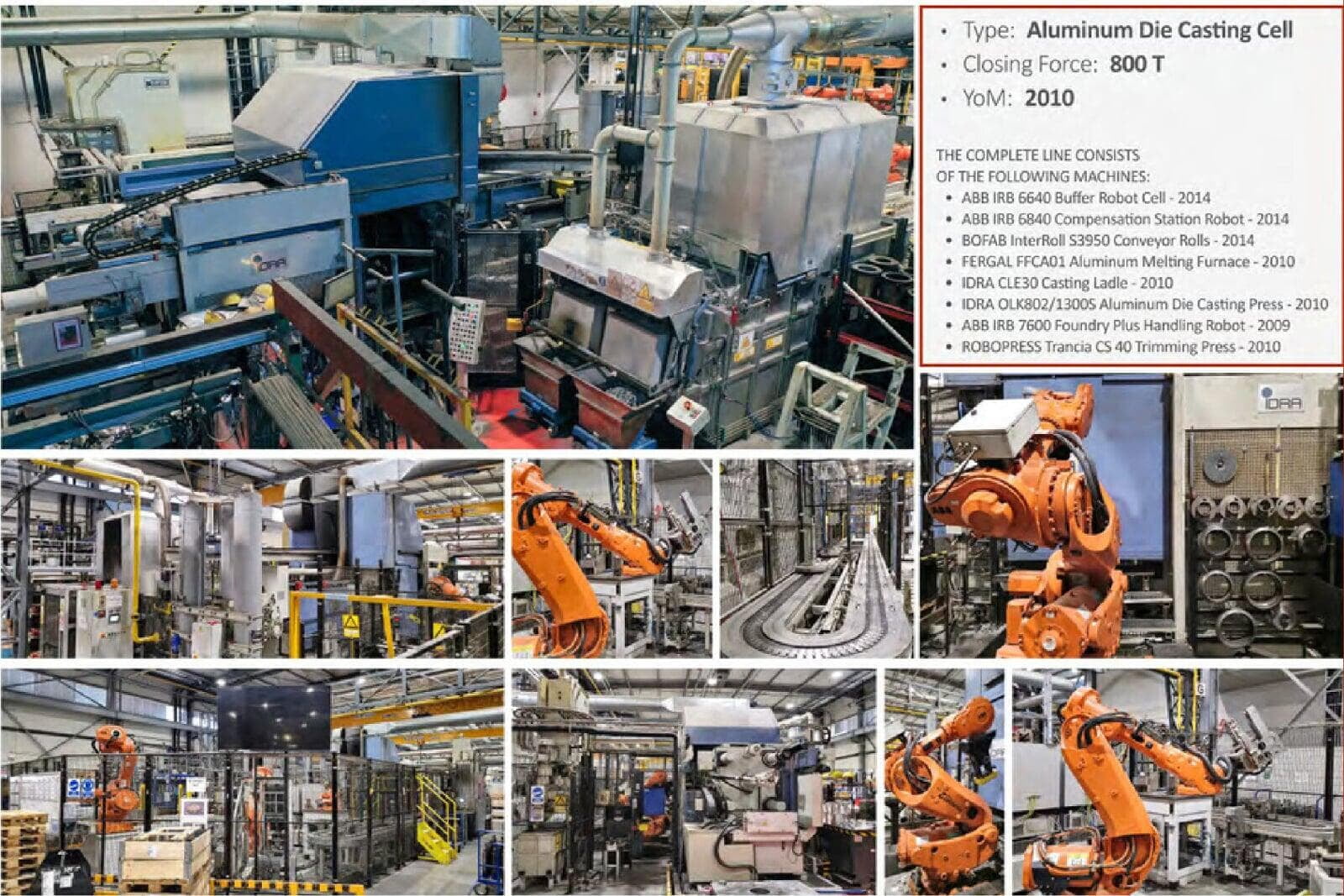

3. IDRA Aluminum Die Casting Cell – Installed in 2010

- ABB IRB 6640 Buffer Robot Cell – 2014

- ABB IRB 6840 Compensation Station Robot – 2014

- BOFAB InterRoll $3950 Conveyor Rolls – 2014

- FERGAL FFCA01 Aluminum Melting Furnace – 2010

- IDRA CLE30 Casting Ladle – 2010

- IDRA OLK802/13005 Aluminum Die Casting Press – 2010

- ABB IRB 7600 Foundry Plus Handling Robot – 2009

- ROBOPRESS Trancia CS 40 Trimming Press – 2010

4. HYUNDAI WIA Stator Housing Machining Line – Installed in 2015

- PREVAS Sinad 50-65-70 Induction Heating Station – 2016

- ABB IRB 7600 Handling Robot – 2015

- HYUNDAI WIA IN BOORM Vertical Turning Lathe – 2015

- CAMPOJAT Sentry1 Gantry – 2015

- HYFRA Sigma 56-5 Chiller Unit – 2015

- UNIROLTECH Conveyor System – 2015

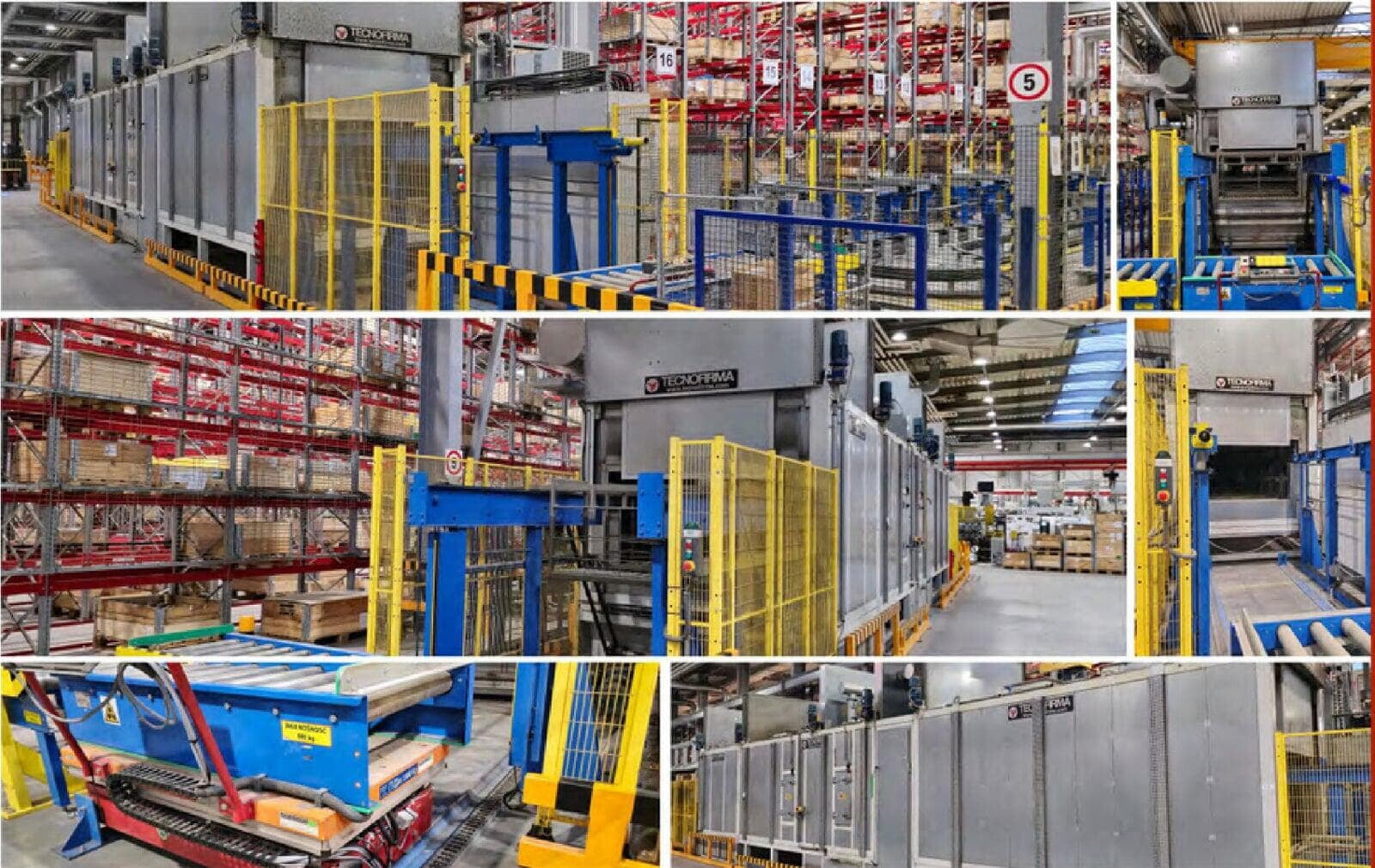

5. TECNOFIRMA Impregnation Machining Line – Installed in 2012

6. VIRTANEN Stator Press Machining Line – Installed in 2015

Capabilities:

Manufacturing Setup 3: Rotor & Stator Production Line

Frame Sizes: 160-200

Power Capacities: 11-37 kW

This modern production line is equipped with the latest technology for small to medium motor production, covering frame sizes 160-200 and power outputs from 11 to 37 kW. Featuring a WEINGARTEN Lamination Press (2019), ABB/CO Automation Welding Cell (2019), and BÜHLER Aluminum Die Casting Cell (2019), this line ensures high precision, efficiency, and reliability in the manufacturing of rotors and stators for various motor applications.

Frame Sizes: 160-200

Power Capacities: 11-37 kW

This modern production line is equipped with the latest technology for small to medium motor production, covering frame sizes 160-200 and power outputs from 11 to 37 kW. Featuring a WEINGARTEN Lamination Press (2019), ABB/CO Automation Welding Cell (2019), and BÜHLER Aluminum Die Casting Cell (2019), this line ensures high precision, efficiency, and reliability in the manufacturing of rotors and stators for various motor applications.

Key Equipment:

Key Equipment:

1. WEINGARTEN Lamination Press (2019)

- SERVO PRESSE SMD 400 15 Decoiler – 1977/2019

- 15R82 Welding/Scissors – 1977/2019

- WEINGARTEN RAS 40 Straightener – 1977/2019

- AWEBA Mechanical Feeder – 1977/2019

- WEINGARTEN HS 315 Lamination Press – 1977/2019

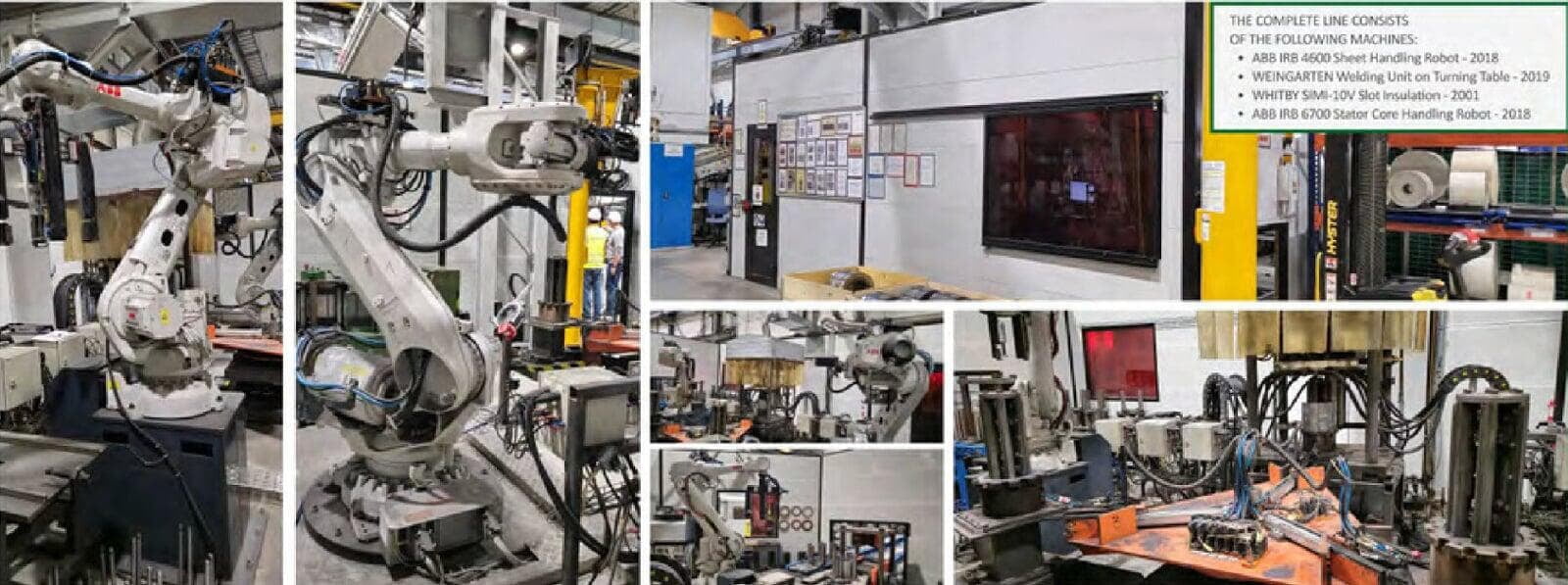

2. ABB/CO Automation Welding Cell (2019)

- ABB IRB 4600 Sheet Handling Robot – 2018

- WEINGARTEN Welding Unit on Turning Table – 2019

- WHITBY SIMI-10V Slot Insulation – 2001

- ABB IRB 6700 Stator Core Handling Robot – 2018

3. BÜHLER Aluminum Die Casting Cell (1995)

- ABB IRB 4600 M2004 Robot Cell – 2015

- ABB IRB 6640 M2004 Robot Cell – 2014

- STOTEK SMW-65F Low-Pressure Die Casting Machine – 2015

- ALTEK Coll Turner with Roller Track – 2015

4. CASSIOLI Automatic Transport Sysytems (2019)

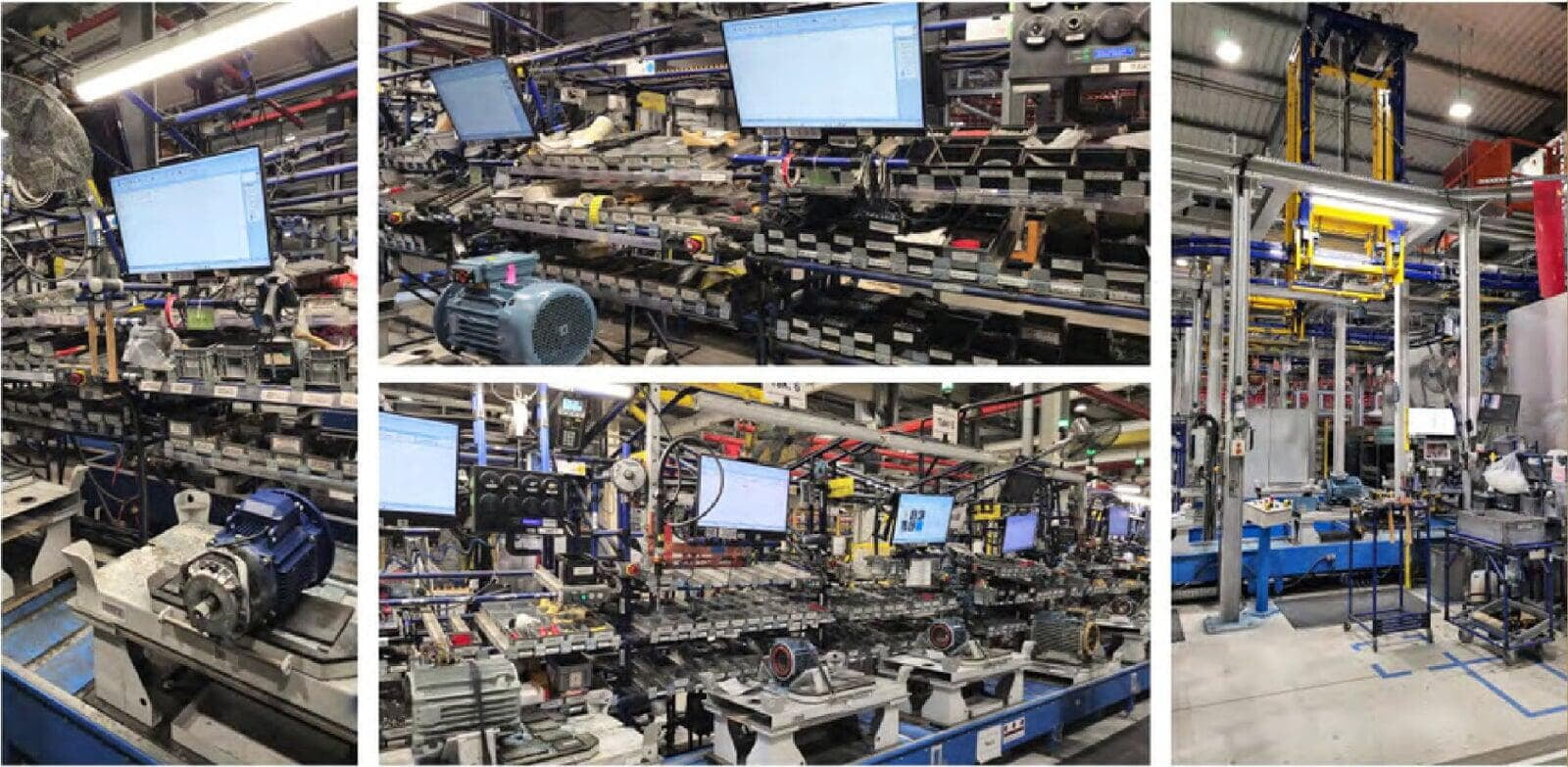

5. Assembly Line for Electric Motors 160-255 (2020)

6. TEPRON Painting Line (2015)

Capabilities:

Low Voltage Industrial Performance Motors

We are proud to offer a range of high-performance industrial machinery assets for sale, sourced from a state-of-the-art manufacturing facility. These assets are specifically designed for the production of low-voltage motors, including robust press lines and automated welding systems, all engineered to meet demanding production requirements with reliability and precision.

Industrial Performance Aluminum Motors

Industrial Performance Steel Motors

Industrial Performance Cast Iron Motors

Contact Us

For inquiries or further details about our rotor and stator production line or low-voltage industrial performance motors, please reach out to us today!

+91 86109 25352 /

+49 178 2862150(WhatsApp)

info@keyleerkorb.com