AUMANN 61457-00-00-00, PM5 (Option2), film mounting system

Non-returnable

₹1,200,000.00

Aumann 61457-00-00-00 PM5

Article number:

DV10143

Manufacturer:

Aumann

Manufacturer number:

61457-00-00-00

Type:

PM5

Serial number:

61457_01.02.2019

YoM:

2020

Condition:

Used

Location

Germany

Availability:

immediately

Choose Quantity

Product Details

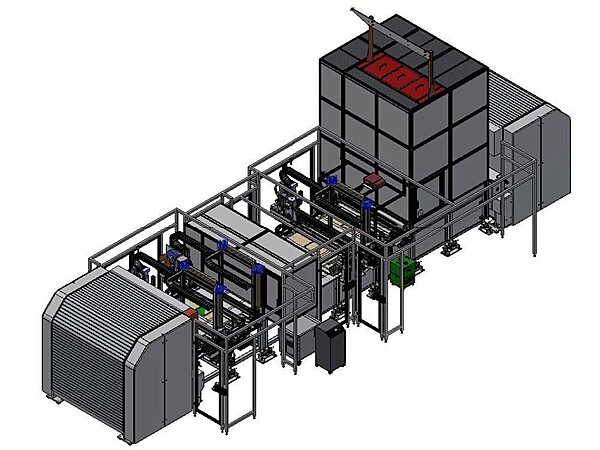

Aumann Limbach Oberfrohna GmbH Cross-Connector-Applikation & Flasher Test, Assembly system for producing contact openings and electrical connections, PM5 Option 2, 61457 00 00 00

Model: PM5 Option 2

Type: Assembly system

Series: 61457000000

Year of manufacture: 2020

General:

The system is used to produce contact openings and electrical connections for the subsequent assembly of a contact box in a flexible PV film. This is/will be unwound/wound onto a coil and transported to the individual processing stations with the aid of winders and unwinders.

Technical data:

Operating voltage: 400V AC

Backup fuse: 50A

Frequency: 50Hz

Electrical connection power: 19.1kW

Control voltage: 24V DC

Air pressure: 6 bar

Production capacity: 20 x 2 m modules/h

Degree of automation: fully automatic

Dimensions: 12.5 x 5.2 x 4 m (width x height x depth)

Stations:

Unwinder:

This station picks up the coil and unwinds the product part.

Manufacturer: Robust Habicht & Heuser GmbH & Co. KG

Type: URM-1400

Cosmetic tape applicator:

Applies cosmetic tape to the rear edge of the module on the product part using an applicator.

Manufacturer: Printum

Laser cell:

Production of contact openings using a laser on the rear module edge of the product part and testing of the correct opening of the contacts using pneumatic Ignun contact pins.

Manufacturer: ACSYS Lasertechnik GmbH

CO² Laser INLINER II 40W CO2

Inspection station:

Empty cell for conducting tests on test material.

Transfer tape application cell:

Application of transfer tape to the rear module edge of the product part using an applicator.

Contact tape application cell:

Insertion of preforms (solder pads) into the opened contact openings and subsequent application of contact tape to the rear module edge of the product part using an applicator.

Soldering station:

Establishing electrical contacts by soldering the preforms (solder pads) to the contact tape.

Manufacturer: ATN Automatisierungstechnik Niemeier GmbH

Flasher station:

Checking the functionality of the product part by flashing and simultaneous contacting using pneumatic Ignun contact pins.

Manufacturer: WAVELABS Solar Metrology Systems GmbH

Type: WLAAA0039

Designation: Module flasher

Empty cell:

Currently no processing of the product part.

Winder:

This station picks up the coil and winds the product part.

Manufacturer: Robust Habicht & Heuser GmbH & Co. KG

Type: URM-1400

Accessories:

Additional Kaeser screw compressor Aircenter SM10 (8 bar, 5.5 kW, year of manufacture: 2020)

Maintenance history

Operating instructions in German in PDF format

Note on condition:

PU 3 + 2 traction rollers have been removed

Model: PM5 Option 2

Type: Assembly system

Series: 61457000000

Year of manufacture: 2020

General:

The system is used to produce contact openings and electrical connections for the subsequent assembly of a contact box in a flexible PV film. This is/will be unwound/wound onto a coil and transported to the individual processing stations with the aid of winders and unwinders.

Technical data:

Operating voltage: 400V AC

Backup fuse: 50A

Frequency: 50Hz

Electrical connection power: 19.1kW

Control voltage: 24V DC

Air pressure: 6 bar

Production capacity: 20 x 2 m modules/h

Degree of automation: fully automatic

Dimensions: 12.5 x 5.2 x 4 m (width x height x depth)

Stations:

Unwinder:

This station picks up the coil and unwinds the product part.

Manufacturer: Robust Habicht & Heuser GmbH & Co. KG

Type: URM-1400

Cosmetic tape applicator:

Applies cosmetic tape to the rear edge of the module on the product part using an applicator.

Manufacturer: Printum

Laser cell:

Production of contact openings using a laser on the rear module edge of the product part and testing of the correct opening of the contacts using pneumatic Ignun contact pins.

Manufacturer: ACSYS Lasertechnik GmbH

CO² Laser INLINER II 40W CO2

Inspection station:

Empty cell for conducting tests on test material.

Transfer tape application cell:

Application of transfer tape to the rear module edge of the product part using an applicator.

Contact tape application cell:

Insertion of preforms (solder pads) into the opened contact openings and subsequent application of contact tape to the rear module edge of the product part using an applicator.

Soldering station:

Establishing electrical contacts by soldering the preforms (solder pads) to the contact tape.

Manufacturer: ATN Automatisierungstechnik Niemeier GmbH

Flasher station:

Checking the functionality of the product part by flashing and simultaneous contacting using pneumatic Ignun contact pins.

Manufacturer: WAVELABS Solar Metrology Systems GmbH

Type: WLAAA0039

Designation: Module flasher

Empty cell:

Currently no processing of the product part.

Winder:

This station picks up the coil and winds the product part.

Manufacturer: Robust Habicht & Heuser GmbH & Co. KG

Type: URM-1400

Accessories:

Additional Kaeser screw compressor Aircenter SM10 (8 bar, 5.5 kW, year of manufacture: 2020)

Maintenance history

Operating instructions in German in PDF format

Note on condition:

PU 3 + 2 traction rollers have been removed