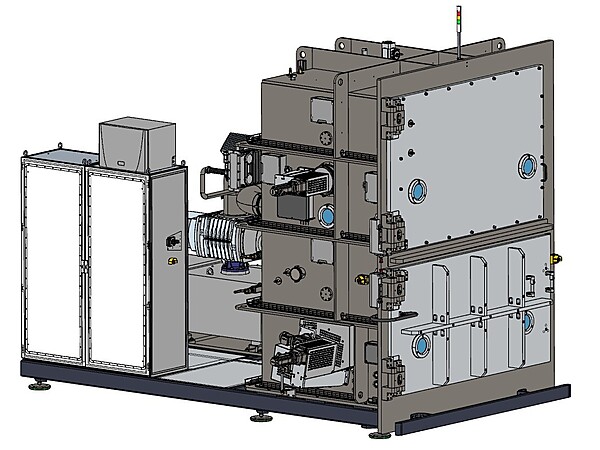

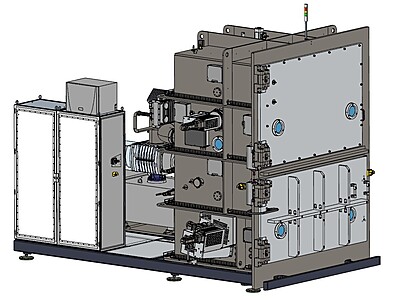

HS-GROUP VD-1350-S, high vacuum drying system

Non-returnable

₹7,000,000.00

HS-Group VD-1350-S

Article number:

DV10151

Manufacturer:

HS-Group

Manufacturer number:

VD-1350-S

Serial number:

M-0102

YoM:

2019

Condition:

Used

Location

Germany

Availability:

immediately

Choose Quantity

Product Details

HS-Group GmbH high-vacuum drying system, VD 1350 S

Model: VD1350S

Year of manufacture: 2019

General:

Stainless steel vacuum chamber: The system consists of a stainless steel vacuum chamber with connected vacuum pumps and process gases. Eleven radiant heaters are installed in the vacuum chamber, between which the substrate film is wound. Cooling plates are located around the hot area where the heaters are located. These prevent the heaters from radiating onto the outer walls of the vacuum chamber. Forepump station: Rotary vane pump Sogevac SV-630BF Roots pump RUVAC WH4400 11KW High vacuum pumps: MAG W 2200 iP turbomolecular pump The vacuum chamber is first evacuated to a process pressure of approx. 2 x 10-1 mbar to 2 x 10-2 mbar. Once the process pressure has been reached, the film substrate can be rewound several times between the upper and lower winders. The edge structure of the substrate is monitored and corrected by a web edge control system. It is essential to rewind at least twice, as loading and unloading can only be carried out on one side of the winding section. The loading and unloading point is located in the lower part of the chamber. The drying process is accelerated by switching on several heating sections. After the drying process is complete, the chamber can be evacuated to a high vacuum pressure of < 5 x 10-5 mbar via connected turbomolecular pumps. Once the final pressure has been reached, a residual gas analysis (RGA) can be performed. Integrated visualization software with data logging and recipe management enables the visual representation and operation of the system.

Technical data:

Operating voltage: 400V AC, 3PH/PE

Frequency: 50Hz

Connected load: 110kVA

Supply fuse: 200A

Production capacity: depending on the material to be processed, 20m/min / 6" core up to max. 830mm diameter/ up to 1.4t

Degree of automation: fully automatic

Stations/equipment:

Vacuum chamber made of stainless steel 1.4301, rectangular, vertically integrated.

Internal dimensions approx. 2670 × 1925 × 3440 mm (approx. 17.7 m³).

Two doors made of aluminum 3.3547, one service door and one loading door.

Two viewing windows with approx. 60 mm diameter for process observation.

Vacuum system equipped with two MAG W 2200 iP turbomolecular pumps (approx. 2100 l/s N₂),

one SOGEVAC SV-630BF backing pump (700 m³/h), and one RUVAC WH4400 roots pump (4400 m³/h).

High-vacuum gate valves DN250 (2×) and chamber valve DN200.

Vacuum measurement using Pirani sensors (5·10⁻⁴ to 1000 mbar) and high-vacuum gauge (5·10⁻⁹ to 1000 mbar).

Multiple ISO-K feedthroughs (2× DN100, 2× DN250).

Substrate heating system with 11 individually adjustable zones, each 5 kW.

Temperature range 20–250 °C, control accuracy ±1 °C, fine adjustment ±10%.

Radiation heating, single-sided onto the inner substrate surface (freespan).

Infrared temperature sensor (Raytec) for continuous substrate temperature monitoring.

Control via solid-state relays and Siemens Profibus.

Gas supply via MFC for 50,000 sccm N₂ (customer-side inlet).

Residual gas analysis (RGA) HPQ3S by MKS Instruments, CF40 port.

Winding and web transport unit for PET/PI films with 50–225 µm thickness.

Film width 1230–1350 mm, maximum diameter 800 mm, maximum roll weight 900 kg.

Cooling and master drive roller Ø 320 mm, double-walled, chrome-plated, water-cooled.

13 deflection rollers Ø 107 mm, polished aluminum.

Winding shafts: 2× interchangeable lower shafts, 1× fixed upper shaft (VT6 40–50 interface).

Tension and length control via incremental encoder, web tension 50–500 N (±3%).

Optical edge guiding system for 1230–1350 mm, repeat accuracy ±1 mm.

Integrated splicing and adhesive system for 80 mm tape, tensile strength up to 500 N.

Control system based on Siemens S7-300 PLC, large Rittal control cabinet (IP54).

Industrial PC with 24" HMI, Windows 10 LTS, 64 GB RAM, 500 GB HDD.

Data acquisition for pressure, temperature, RGA, DMC, recipe, coil ID, and timestamp logging.

Interfaces include XML/TCP DMC reader.

Utility system with stainless steel cooling-water distribution, heat exchanger, and a dedicated cooling circuit.

Compressed air maintenance unit with water separator and pressure gauge.

Accessories:

Maintenance history available

Documentation available

Model: VD1350S

Year of manufacture: 2019

General:

Stainless steel vacuum chamber: The system consists of a stainless steel vacuum chamber with connected vacuum pumps and process gases. Eleven radiant heaters are installed in the vacuum chamber, between which the substrate film is wound. Cooling plates are located around the hot area where the heaters are located. These prevent the heaters from radiating onto the outer walls of the vacuum chamber. Forepump station: Rotary vane pump Sogevac SV-630BF Roots pump RUVAC WH4400 11KW High vacuum pumps: MAG W 2200 iP turbomolecular pump The vacuum chamber is first evacuated to a process pressure of approx. 2 x 10-1 mbar to 2 x 10-2 mbar. Once the process pressure has been reached, the film substrate can be rewound several times between the upper and lower winders. The edge structure of the substrate is monitored and corrected by a web edge control system. It is essential to rewind at least twice, as loading and unloading can only be carried out on one side of the winding section. The loading and unloading point is located in the lower part of the chamber. The drying process is accelerated by switching on several heating sections. After the drying process is complete, the chamber can be evacuated to a high vacuum pressure of < 5 x 10-5 mbar via connected turbomolecular pumps. Once the final pressure has been reached, a residual gas analysis (RGA) can be performed. Integrated visualization software with data logging and recipe management enables the visual representation and operation of the system.

Technical data:

Operating voltage: 400V AC, 3PH/PE

Frequency: 50Hz

Connected load: 110kVA

Supply fuse: 200A

Production capacity: depending on the material to be processed, 20m/min / 6" core up to max. 830mm diameter/ up to 1.4t

Degree of automation: fully automatic

Stations/equipment:

Vacuum chamber made of stainless steel 1.4301, rectangular, vertically integrated.

Internal dimensions approx. 2670 × 1925 × 3440 mm (approx. 17.7 m³).

Two doors made of aluminum 3.3547, one service door and one loading door.

Two viewing windows with approx. 60 mm diameter for process observation.

Vacuum system equipped with two MAG W 2200 iP turbomolecular pumps (approx. 2100 l/s N₂),

one SOGEVAC SV-630BF backing pump (700 m³/h), and one RUVAC WH4400 roots pump (4400 m³/h).

High-vacuum gate valves DN250 (2×) and chamber valve DN200.

Vacuum measurement using Pirani sensors (5·10⁻⁴ to 1000 mbar) and high-vacuum gauge (5·10⁻⁹ to 1000 mbar).

Multiple ISO-K feedthroughs (2× DN100, 2× DN250).

Substrate heating system with 11 individually adjustable zones, each 5 kW.

Temperature range 20–250 °C, control accuracy ±1 °C, fine adjustment ±10%.

Radiation heating, single-sided onto the inner substrate surface (freespan).

Infrared temperature sensor (Raytec) for continuous substrate temperature monitoring.

Control via solid-state relays and Siemens Profibus.

Gas supply via MFC for 50,000 sccm N₂ (customer-side inlet).

Residual gas analysis (RGA) HPQ3S by MKS Instruments, CF40 port.

Winding and web transport unit for PET/PI films with 50–225 µm thickness.

Film width 1230–1350 mm, maximum diameter 800 mm, maximum roll weight 900 kg.

Cooling and master drive roller Ø 320 mm, double-walled, chrome-plated, water-cooled.

13 deflection rollers Ø 107 mm, polished aluminum.

Winding shafts: 2× interchangeable lower shafts, 1× fixed upper shaft (VT6 40–50 interface).

Tension and length control via incremental encoder, web tension 50–500 N (±3%).

Optical edge guiding system for 1230–1350 mm, repeat accuracy ±1 mm.

Integrated splicing and adhesive system for 80 mm tape, tensile strength up to 500 N.

Control system based on Siemens S7-300 PLC, large Rittal control cabinet (IP54).

Industrial PC with 24" HMI, Windows 10 LTS, 64 GB RAM, 500 GB HDD.

Data acquisition for pressure, temperature, RGA, DMC, recipe, coil ID, and timestamp logging.

Interfaces include XML/TCP DMC reader.

Utility system with stainless steel cooling-water distribution, heat exchanger, and a dedicated cooling circuit.

Compressed air maintenance unit with water separator and pressure gauge.

Accessories:

Maintenance history available

Documentation available