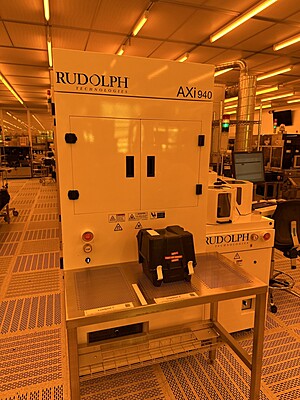

Rudolph AXi940 Inline Wafer Inspection Tool

₹22,000,000.00

Rudolph AXi940 Inline Wafer Inspection Tool

Article number:DV10120

Manufacturer:Rudolph

Manufacturer number:AXi940

Type:Inline Wafer Inspection Tool

YoM:2010

Condition:Used

Location Schweiz

Schweiz

Schweiz

SchweizAvailability:as of 06/2025

Choose Quantity

Product Details

Rudolph Technologies / Onto Innovation automatic inline wafer inspection tool AXi 940 b

Model: AXi940b

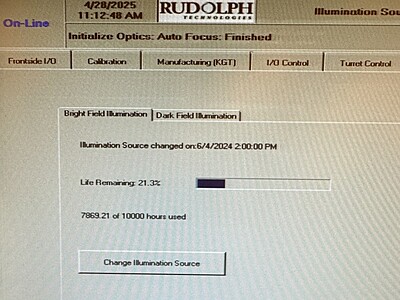

Operating hours lamp: <8.000h

Year of manufacture: 07/2010

Technical data:

AXi-940b:

200-240V AC

50/60Hz

6A

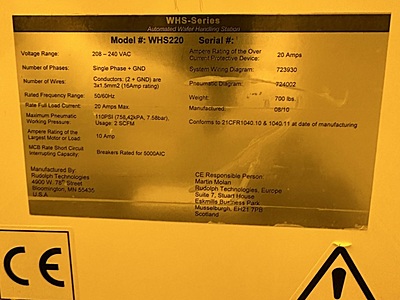

WHS220:

208-240V AC

50/60Hz

max. 20A

110psi

Features:

o Loading connections for 6 and 8 inch wafers

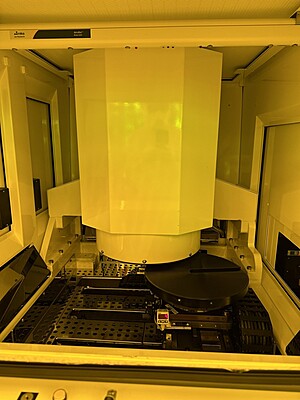

o Handler, robot and prealigner internal

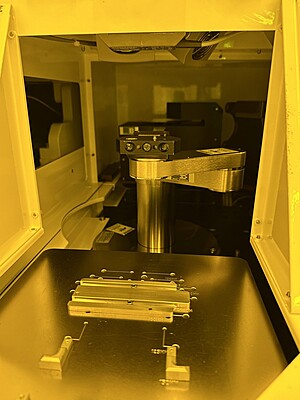

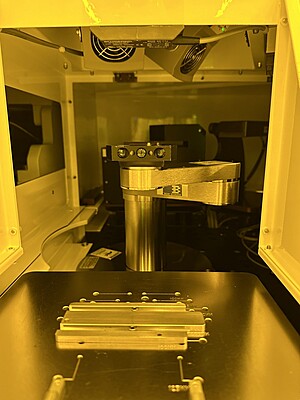

o Lenses 1x 2x 5x 10x 20x

o Internal barcode reader

o Inspection camera b/w

o Colour review camera

o Frontsite and clustersite computer (WIN7)

o Software Version 3.9.4.18

Accessories:

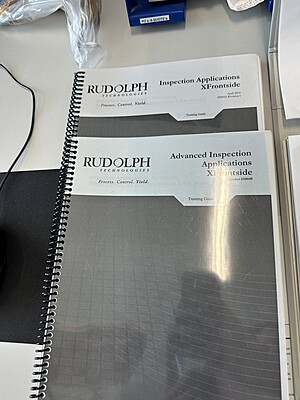

Documentation

General information about the system:

The Rudolph AXi940 is an automated macro inspection system specifically designed for front side inspection of semiconductor wafers. The system was introduced by Rudolph Technologies (now part of Onto Innovation) and is part of the ‘Explorer Inspection Cluster’ - a modular platform for inspecting multiple wafer surfaces.

Inspection area:

The AXi940 is designed for macroscopic inspection of the wafer front surface and is primarily used to detect macro defects.

Software:

The system features a modernised user interface designed to reduce operating costs through increased productivity, higher system reliability and minimised operator interaction.

Automation:

Integrated, intelligent software supports the automatic creation of inspection recipes. This significantly reduces the time required and the need for manual intervention by the operator.

System integration:

The AXi940 can be fully integrated into the Explorer Inspection Cluster as a module. It can be operated offline for recipe creation while parallel production processes in other modules continue undisturbed.

Installation dimensions:

approx. 2x1.5x2m

Commissioning:

Commissioning of the system can be organised by the manufacturer through us and carried out on your premises for an additional charge. Simply ask us about this.

Maintenance:

The system was last serviced in 2024.

Professional maintenance of the system can optionally be carried out by the manufacturer. This service is subject to a charge and can be ordered and organised through us.

Upgrading the wafer size:

A professional upgrade of the wafer size can optionally be carried out by the manufacturer. This service is subject to a charge and can be ordered and organised through us.

Model: AXi940b

Operating hours lamp: <8.000h

Year of manufacture: 07/2010

Technical data:

AXi-940b:

200-240V AC

50/60Hz

6A

WHS220:

208-240V AC

50/60Hz

max. 20A

110psi

Features:

o Loading connections for 6 and 8 inch wafers

o Handler, robot and prealigner internal

o Lenses 1x 2x 5x 10x 20x

o Internal barcode reader

o Inspection camera b/w

o Colour review camera

o Frontsite and clustersite computer (WIN7)

o Software Version 3.9.4.18

Accessories:

Documentation

General information about the system:

The Rudolph AXi940 is an automated macro inspection system specifically designed for front side inspection of semiconductor wafers. The system was introduced by Rudolph Technologies (now part of Onto Innovation) and is part of the ‘Explorer Inspection Cluster’ - a modular platform for inspecting multiple wafer surfaces.

Inspection area:

The AXi940 is designed for macroscopic inspection of the wafer front surface and is primarily used to detect macro defects.

Software:

The system features a modernised user interface designed to reduce operating costs through increased productivity, higher system reliability and minimised operator interaction.

Automation:

Integrated, intelligent software supports the automatic creation of inspection recipes. This significantly reduces the time required and the need for manual intervention by the operator.

System integration:

The AXi940 can be fully integrated into the Explorer Inspection Cluster as a module. It can be operated offline for recipe creation while parallel production processes in other modules continue undisturbed.

Installation dimensions:

approx. 2x1.5x2m

Commissioning:

Commissioning of the system can be organised by the manufacturer through us and carried out on your premises for an additional charge. Simply ask us about this.

Maintenance:

The system was last serviced in 2024.

Professional maintenance of the system can optionally be carried out by the manufacturer. This service is subject to a charge and can be ordered and organised through us.

Upgrading the wafer size:

A professional upgrade of the wafer size can optionally be carried out by the manufacturer. This service is subject to a charge and can be ordered and organised through us.